Sentinel completes U.S. Navy’s six-tug order from Dakota Creek

Sentinel completes U.S. Navy’s six-tug order from Dakota Creek

The U.S. Navy developed the YT 808 series with the goal of upgrading its fleet of ship-assist tugboats. With the delivery of YT 813/Sentinel in late March, that mission is accomplished.

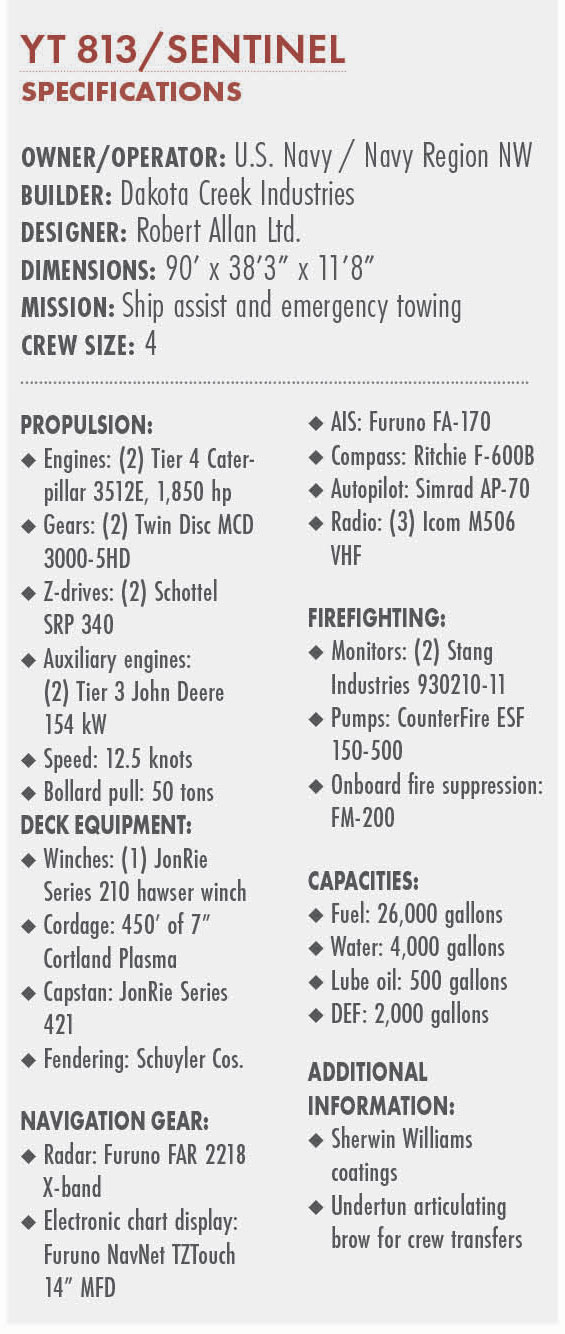

The 90-by-38-foot Sentinel is the sixth and final vessel in the series featuring the Robert Allan Ltd. Z-Tech 4500 design. Dakota Creek Industries built the six tugs at its Anacortes, Wash., yard. Five tugs operate in the Pacific Northwest, where they assist vessels of all sizes, including submarines. One is based at Portsmouth Naval Shipyard in Kittery, Maine.

The vessels are powered by twin 1,850-hp Caterpillar 3512 Tier 4 engines paired with Schottel z-drives through Twin Disc reduction gears. Two John Deere engines provide electrical power, and the JonRie InterTech winch and capstan facilitate towing and line-handling.

Capt. Tim Hartman, port operations director for Navy Region Northwest, said the five YT 808 series tugboats operating in the Pacific are performing admirably.

“The YT 808 class vessels are meeting expectations for the Navy and the Puget Sound,” he said. “The new tug complements our operation and gives the Navy a tool that will adapt to changes well into the future.”

The YT 808 series represents a modernization of the six YT-802 series tugboats delivered a decade ago by the former J.M. Martinac Shipbuilding in Tacoma, Wash. Naval architects at Robert Allan Ltd. in Vancouver, B.C., modified their existing Z-Tech 6000 series to meet the Navy’s design goals. The result was a new design known as the Z-Tech 4500.

The Navy kept the same Z-Tech 4500 design for the YT 808 class with some modern enhancements. Tugs in the new series have the first EPA Tier 4-rated engines in the Navy’s tugboat fleet. The engine room was redesigned to accommodate the engines and their selective catalytic reduction (SCR) units. New tankage also was added to hold 2,000 gallons of diesel exhaust fluid.

The Navy conceived the new series to replace its aging fleet of YTB tugboats, according to Dan Shimooka with the Navy’s office of Service Craft & Seaborne Targets. American shipbuilders delivered 77 of these single-screw, 2,000-hp tugs in the 1960s and 1970s. Many later entered service for private tugboat companies or were sold to U.S. allies overseas.

The Navy has stricken three single-screw YTB tugboats from its Northwest fleet — a region that includes Puget Sound Naval Shipyard, Naval Submarine Base Bangor and Naval Station Everett — with the arrival of the YT 808 series. The last three YTBs working in the fleet are based in Guantanamo Bay, Cuba.

The retirement of the three YTB boats in Navy Region Northwest is bittersweet for Capt. John Trail, the region’s port captain. He operated the YTB tugs for more than a decade and is sad to see the old vessels go. Still, he readily admits the new tugboats can do things the older ones cannot.

“The Navy has a lot of high-sided auxiliary vessels and … these have a high sail area,” Trail said in a recent interview. “You needed three to four YTBs to moor and unmoor these vessels. But with the new tugs with these z-drives and the horsepower and indirect towing, it is safer and easier to get the ship moored.”

Line handling on the modern tugs is also safer, Trail said. What used to take three or four crewmembers to make up a tow can now be done with a single deck hand. That means fewer people on deck, especially when the line is under pressure. The z-drive tugs also are at a much lower risk of being girded than the YTB tugs.

The five YT 808 series tugboats in Washington do a little of everything for the Navy. They assist ships into and out of berths, maneuver vessels into drydock and shift barges from one installation to another. They also work submarines.

The Navy installed a custom articulating brow on the YT 808 series to facilitate safe personnel transfers between the tug and the submarine. The system extends from the tugboat to the deck of the sub. Undertun, of Norway, originally developed the retractable brow system for personnel transfers in the offshore wind industry.

“Transferring the ship pilot from a submarine or surface ship, the brow has streamlined the movement of personnel and equipment,” Capt. Hartman said.

The YT 808 series has an extensive fendering package from Schuyler Cos. to handle different Navy ships. The leading edge of the skeg, for instance, is covered in rubber to allow the tugs to nudge the vessels into position. Two layers of cylindrical rubber on the bow ensure soft contact against Navy ships. Angled fenders on the port and starboard sides facilitate solid connections when making up to barges on the hip. Above the waterline, Schuyler installed gray rubber to avoid scuffing the hulls of Navy ships.

The Navy’s Northwest region operates eight tugboats, each of which has a four-person crew that works a 40-hour week. The crews rarely sleep on the tugs, although they have accommodations for six people. The vessels also have a functional galley and mess.

Below deck, the engine room offers plenty of room to service key systems. The 1,850-hp Cat engines occupy the port and starboard sides of the engine space, with the John Deere gensets positioned along the centerline. The starboard main engine drives a CounterFire fire pump that feeds up to 2,000 gpm to twin forward-facing Stang fire monitors installed on the second deck.

Bollard pull runs just under 50 tons ahead and astern for the new series. That’s plenty of power to handle Navy ships, including aircraft carriers, operating in the Pacific Northwest.

“The horsepower is just right,” Trail said. “With the new destroyers, which are 510 feet by 50 feet with a 38-foot draft, these tugs will still pull them all over. And for an aircraft carrier, they are just excellent.”

The six tugs in the series are officially known as YT 808 through YT 813. Yet each also has a local name based on a prominent nearby mountain. The six tugs, in sequential order from YT 808, are known as Rainier, Agamenticus, Deception, Olympus, Baker and Sentinel.

Shimooka, whose office oversaw the program, said the YT 808 series has proven to be successful. “All of the tugs were placed into service almost immediately upon delivery with very few warranty issues encountered. Dakota Creek Industries did a fantastic job constructing the tugs.”

Liz Stout, Dakota Creek’s new construction and major repair project manager, said the yard is proud to have built six extremely efficient, clean “absolute workhorses.”

“Once we worked through the challenges of labor and material delays due to COVID, we were able to gain momentum and deliver 4 tugs in 6 months in 2021 and 18 months between the first and last delivery,” she recalled.

Hartman, summing up the YT 808 series, offered this description: They’re the right tool for the job.