Latest Seabulk Rotortugs add power and bollard pull

Latest Seabulk Rotortugs add power and bollard pull

Seabulk Towing welcomed the first Advanced Rotortug (ART) to American shores in 2017. Fast-forward five years: the company now operates four of the specialized triple-screw tugboats with a fifth on the way.

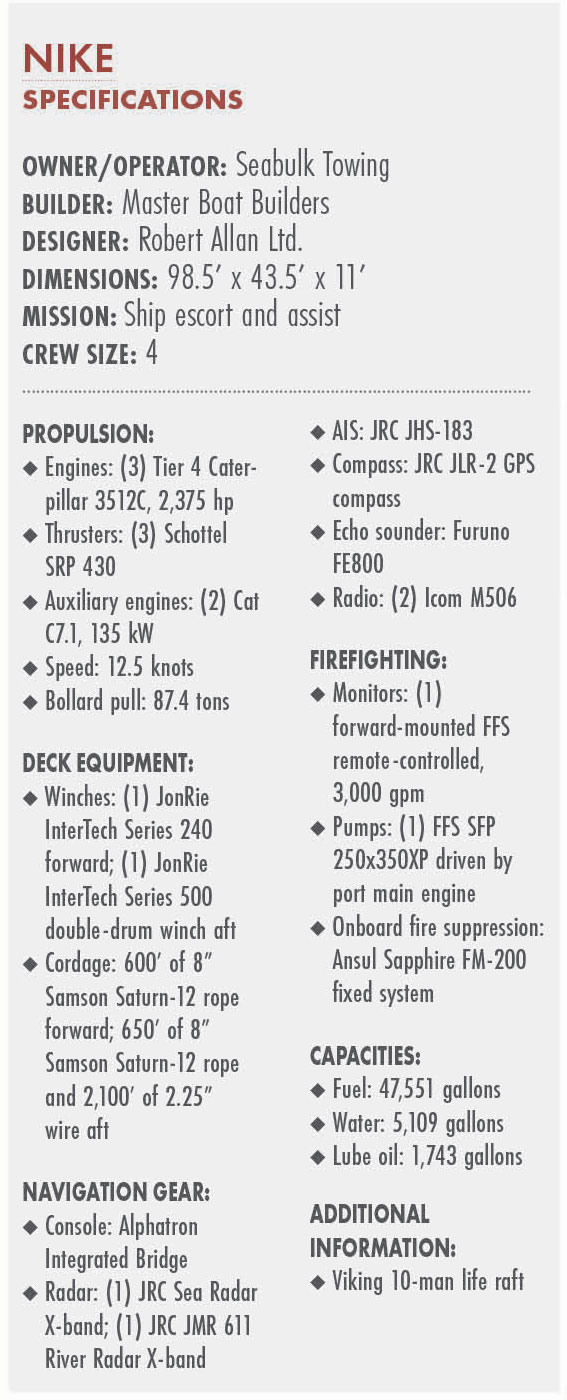

The 98-foot Nike is the first of two ART 90-98US tugboats due from Master Boat Builders using a design from naval architects at Robert Allan Ltd. Nike, named for the Greek goddess of victory, entered service in Mobile, Ala., in October 2021. The second tugboat in the series, Hermes, is due this summer.

Nike, like other ARTs working around the world, has three main engines and three z-drive thrusters in a triangular pattern under the keel. Two drives are forward, one on the port and starboard sides, and one is aft along the centerline.

“For tight-quarters operations, this tugboat is pretty phenomenal,” said Austin Gibbs, the mate on Nike. “It’s a very versatile tug that allows us to accomplish a lot of different maneuvers in a short time.”

Nike represents an upgrade compared to Seabulk’s first three ART 80-98US tugs, Trident, Triton and Trinity, delivered in 2017 and 2018. The horsepower increased by 25 percent, from 5,733 total horsepower to more than 7,100 in the new series. Bollard pull rose with it, from 80 to 90 tons — thus the updated moniker ART 90-98US.

ARTs are known for their maneuverability, their ability to go sideways at a high speed and their ability to exert tremendous sideways force while pacing alongside a moving ship. Although a traditional azimuthing stern drive (ASD) tugboat can pace alongside the ship, it is unable to provide as much sideways force as a Rotortug, explained Lawren Best, director of design development with Robert Allan Ltd.

“Nike is more maneuverable and capable of going sideways at faster speeds and will exert more force for the same bollard pull at speeds under 8 knots,” he explained.

Nike is a good fit for Mobile, which has its share of compact berths and tight spaces to move ever-larger ships. Gibbs said there are sections of the harbor where Seabulk crews have 1,300 feet within a turning basin to spin ships as long as 1,100 feet.

Rotortugs do not have a skeg, which allows them to sidestep much more quickly than a traditional escort tugboat, at speeds up to 8.5 knots. Its absence also reduces turbulence when the tug is approaching a ship at speed. The third engine and drive also gives the tug redundancy: With one engine out, the vessel can still produce around 60 tons of bollard pull.

Another advantage, when called upon to fit longer ships into tight terminals, is a maneuver known as “rotoring.” This is when the tug operates within the beam limits of the ship. When rotoring, the tug’s wash is directed away from the ship, allowing for more efficient control while maneuvering the vessel. And the third drive on ART tugs allows them to perform effective sideways maneuvers in tight spaces where ASD tugs are constrained.

The wheelhouse is equipped with three z-drive controls, two of which are on the port side. That requires some getting used to for operators transitioning from an ASD tug with two hand controls. Some captains use the stern drive to steer the tug, much like a single-screw vessel.

Although the hull form for the five Seabulk Rotortugs is the same, naval architects redesigned the engine room to accommodate the Tier 4 engines and related aftertreatment system. Best said the design placed the selective catalytic reduction (SCR) units horizontally in the ceiling of the engine room.

“But to fit this equipment within the design, we took the unique step of splitting the exhaust after the SCR on one of the three main engines into two smaller exhaust pipes and silencers,” he said.

“This allows one of these smaller exhausts to fit in each of the port and starboard funnels with one of the full-size exhaust pipe and silencer from one of the other two main engines,” Best continued. “This arrangement leads to a very compact arrangement above deck, which provides the master with best possible visibility.”

The three engines are installed in a V-shaped formation in the engine room, with two mains driving the forward z-drives ahead of the aft unit driving the aft thruster. The propulsion package consists of three 2,375-hp Caterpillar 3512E engines driving Schottel SRP 430 z-drives. Electrical power comes from two Tier 3 Cat C7.1 generators producing 150 kW.

The port Cat engine drives an FFS remote-controlled fire pump capable of 3,000 gallons per minute that supplies water to a remote-controlled forward-facing FFS monitor.

Nike, like its older sister tugs, is outfitted with an Alphatron integrated bridge equipped with four collapsible screens. Each can display radar and other information based on the operator’s preference. The vessel has two JRC radars, along with Alphatron and JRC navigation electronics.

Crew spaces on the main level consist of a galley and separate crew mess and lounge. The vessel has berthing for six people in four cabins, although it typically operates with a four-person crew. The tug also has 3 full heads with showers.

JonRie Intertech supplied the Series 240 hawser drum forward and the Series 500 double-drum winch on the aft deck. Both are wrapped with at least 600 feet of Samson Saturn-12 rope.

Garrett Rice, president of Master Boat Builders, recalled an unusual engineering and build period for Nike, which happened almost entirely during the Covid-19 pandemic. “Thankfully, we had really great partners who were understanding of the situation,” he said recently.

Although Nike is very similar to its earlier sister tugs, there were enough changes to keep the shipbuilders on their toes. “This is the same hull form. The technology stayed the same and we understood how to do it. The problem is, with boats that are almost the same, is that they are not the same at all,” Rice said. Even so, he said the yard is proud of the finished product.

So is the team at Seabulk, which built more power into an already maneuverable and proven platform and in the process expanded its capabilities in the growing Port of Mobile.