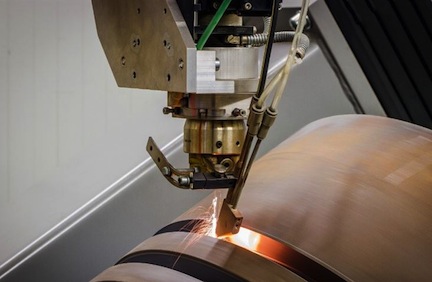

(HELSINKI, Finland) — Wartsila Services’ Business Line QuantiServ, which offers specialized maintenance and repair services for marine and energy customers that operate equipment by multiple brands, is introducing a new robotized laser cladding technology for the reconditioning of large-bore pistons in two-stroke engines.

The new reconditioning process minimizes welding, causes less thermal shock to the base material, and replaces the old chromium layer’s galvanic application.

“In addition to its environmental efficiency, the new coating extends the piston head’s life span and time between overhauls (TBO) compared to conventional chromium layers. We have field-tested the new technology on container vessels, and after 15,000 running hours, the results are very promising, showing excellent running behavior and very low piston wear rates,” said Ole Pyndt Hansen, director, QuantiServ. “Based on these tests, we predict that reconditioning the piston by using the new laser cladding process can almost double its life span."

According to Guido Barbazza, vice president, emerging businesses, Wartsila Services, “this new technology is one of several innovative steps that can bring the traditional reconditioning processes into the digitalized 21st century, while ensuring the predictability of assets for our customers and supporting the Wartsila and QuantiServ vision for setting industry standards for smart and sustainable solutions.”

The new robotized laser cladding technology has been developed in QuantiServ’s Reconditioning knowledge center in Kruiningen, Netherlands. In 2018, this technology will be cloned and available for customers in selected QuantiServ remanufacturing workshops globally. The new can be utilized for countless other applications in the remanufacturing business as well.

For more information, visit www.quantiserv.com.