(VANCOUVER, British Columbia) — With the recent announcement of the HaiSea Marine tug fleet, the maritime industry gained its first glimpse of Robert Allan’s Ltd.’s recent work in battery electric tugboats and their potential to significantly reduce or even eliminate exhaust emissions in ports.

Robert Allan Ltd.’s first entry is a trio of zero-emissions ElectRA 2800 harbor tugs for the aforementioned fleet. With clean hydroelectric power available from the local grid, these tugs’ battery capacity of up to 6,102 kWh will allow them to perform a majority or perhaps even all missions on battery power alone, demonstrating the potential of leveraging battery technology to realize near complete elimination of carbon dioxide (CO2) and other potentially harmful exhaust emissions from harbor tug operations.

Each of the three ElectRA 2800 tugs is expected to eliminate approximately 1,700 tonnes of CO2 per year, thus resulting in total annual savings in excess of 5,000 tonnes compared to even the cleanest modern diesel-powered alternatives. This roughly equates to the carbon emissions of nearly 1,000 cars and is illustrative of the possibilities for some of the world’s busiest marine hubs.

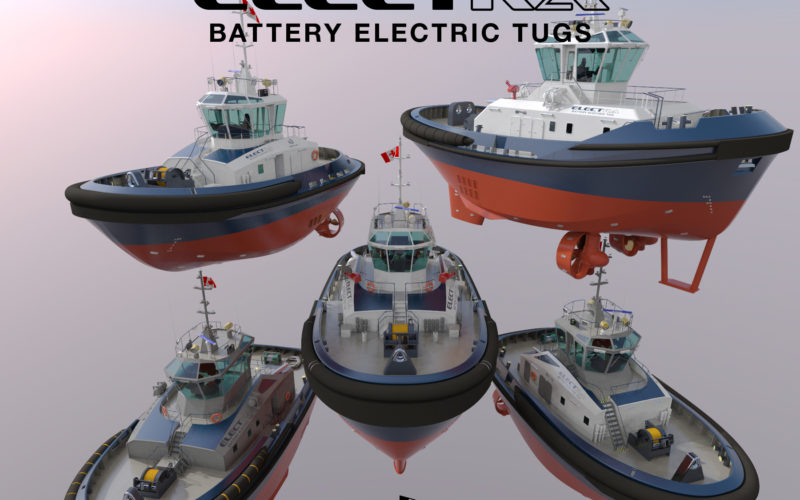

The series has already been rapidly expanding since then, with ElectRA 2100, 2300, 2500 and 2600-T concepts, with each offering a distinctly different take on battery electric propulsion.

The most similar to the HaiSea tugs are the ElectRA 2500 tugs, which still deliver an impressive 70 tonnes of bollard pull and include backup diesel gensets for firefighting and extended endurance, but in a more compact hull form. Boasting approximately 3,200 kWh of batteries, these are still formidable battery electric tugs capable of a wide range of missions including escort.

The ElectRA 2300 recognizes that most battery electric tug applications will be harbor operations, and hence the need for full overnight accommodations is questionable. By sacrificing some of this overnight capacity, these compact tugs feature in excess of 3,500 kWh of battery capacity in a flush deck design, while still being capable of bollard pulls in excess of 60 tonnes and maintaining some backup diesel generator capacity.

The ElectRA 2100 go one step further by eliminating the main gensets altogether, thus also eliminating many of the space-consuming and costly diesel, exhaust, ventilation and cooling systems. Although a small get-home generator remains in the deckhouse, these are pure battery tugs and their battery capacity is thus commensurately large, with a maximum installation in excess of 5,000 kWh. Designed to reduce costs associated with battery electric tugs to a minimum, the batteries on this 50-tonne bollard pull design are of a special type that is also highly economic.

Finally, the ElectRA 2600-T displays the versatility of the series, with nearly 4,000 kWh integrated into a 70-tonne bollard pull tractor tug design. Fully capable of firefighting and escort, these tugs are effectively the tractor tug counterparts to their ElectRA 2500 (ASD) cousins.

As with any Robert Allan Ltd. series, the above are illustrative of the possibilities, but with each to be customized to individual clients’ needs. Customization of a battery electric tug is especially critical to ensure that the battery capacity not only meets the energy needs of the specific operation, but also doesn’t result in excessive investment compared to what is needed. To this end, Robert Allan Ltd. uses its proprietary RAptures program to analyze each individual operation, also calculating CAPEX and OPEX, payback periods, as well as CO2 reductions.

– Robert Allan Ltd.