The following is text of a news release from DNV GL:

(OSLO, Norway) — In collaboration with the Norwegian, Danish and U.S. maritime authorities, battery manufacturers, system integrators, suppliers of fire extinguishing systems, shipyards and shipowners, DNV GL has released a new report on battery safety in ships. The report assesses explosion and fire risks in maritime battery installations and the effectiveness of fire extinguishing systems in the event of a battery fire.

“Batteries on board ships are both environmentally friendly and cost-effective solutions that we wish to see more of in the future. This project has been important in learning the risks of these systems and using the new insight to improve safety requirements,” said Lars Alvestad, acting director of the Norwegian Maritime Authority.

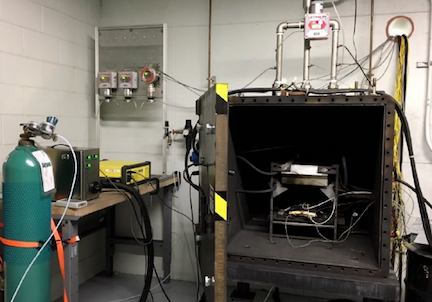

A battery fire can produce very hot fires, as well as the risk of explosion due to gases produced by the battery. DNV GL’s new report presents the results of research on what happens during a fire in a battery compartment, the release of gases, and the usefulness of various extinguishing systems in combating the fire and preventing explosions. One of the most important findings concerns ventilation systems, which are critical to avoiding an accumulation of explosive gas. The report concludes that ventilation alone will not adequately mitigate gas accumulation if a significant portion of the battery system ignites.

"In addition to fire suppression and ventilation, the battery design must have preventative safety barriers so that the fire and gas emissions are limited to as small a part of the battery system as possible," said Henrik Helgesen, project manager and senior consultant at DNV GL.

The report provides new recommendations on ventilation systems, based on a newly created model which identifies the appropriate size and type of ventilation system based on a vessel’s battery installation. Early fire and gas detection are also essential, meaning that the gas sensor should be located as close to the battery as possible.

Launched in 2017, the research project draws on the experience of a wide range of maritime stakeholders. “It is very important for us to work closely with all parts of the industry and understand the full picture as we work to promote safety in our regulatory development work,” said Denis Cederholm-Larsen, senior ship surveyor at the Danish Maritime Authority.

The following partners have contributed to the research:

The Norwegian Maritime Authority

The Danish Maritime Authority

The U.S. Maritime Administration (MarAd)

Norwegian Defence Research Establishment (FFI)

Corvus Energy, supplier of maritime battery systems

FIFI4MARINE, supplier of lithium-ion fire extinguishing systems

Nexceris, developer of technology for battery gas sensors

Kongsberg Maritime (former Rolls-Royce Marine AS), supplier of propulsion technology

ABB, supplier of propulsion technology

Stena, shipowner and ferry operator

Scandlines, shipowner and ferry operator

Damen, shipyard

Marioff, supplier of fire extinguishing systems

Leclanche, supplier of battery systems

Super-B, supplier of battery systems

DNV GL

To access the report, click here.