In a few short months, the San Francisco Bar Pilots will take delivery of a new vessel designed to handle rough waters outside the Golden Gate Bridge.

The 67-foot aluminum launch is under construction at Snow & Company in Seattle. It features the same Camarc Design hull used by pilots up and down the West Coast. The propulsion package sets this vessel apart.

It is among the first pilot boats with engines that meet Environmental Protection Agency (EPA) Tier 4 emission rules. It is also one of the first U.S. vessels designed to accommodate a diesel particulate filter (DPF) that the California Air Resources Board will soon require.

Designing, outfitting and building the launch to meet these combined regulatory standards was no small feat. Bar pilot Capt. David McCloy said finding the right engines was an early challenge.

“We had to pick an engine that would be a good candidate for a DPF,” said McCloy, who has overseen construction for the Bar Pilots. “The (DPFs) do not yet exist for that engine, so we are building it with space and weight allotment for the DPF when they do come out.”

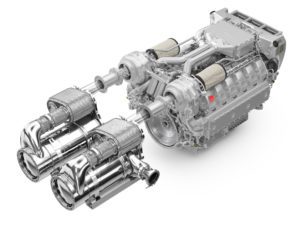

The propulsion package consists of twin 1,200-hp MAN 12-cylinder engines driving HamiltonJet waterjets through Twin Disc gears. Electrical power will come from two Northern Lights gensets. The new launch will have a top speed exceeding 25 knots.

The propulsion package consists of twin 1,200-hp MAN 12-cylinder engines driving HamiltonJet waterjets through Twin Disc gears. Electrical power will come from two Northern Lights gensets. The new launch will have a top speed exceeding 25 knots.

Tugboats, ferries and other commercial workboats have long operated with Tier 4 engines. The EPA has required them to since late 2017 for engines producing more than 804 hp (600 kW). Pilot boats have been slower to adopt these engines for a couple important reasons.

For one, the EPA created an exemption in 2020 for 600- to 1,400-kW engines due to limited availability. The exemption expires at the end of 2022. For another, most pilot boats in the 50- or 55-foot range don’t require this much horsepower to hit their speeds, said Winn Willard, president of Ray Hunt Design, which designs pilot boats for Gladding-Hearn Shipbuilding.

“But, of course, this regulation, like all regulations, will create a distortion in the market, holding boat size down at one end and increasing it at the upper end to accommodate the larger engines and SCR systems,” he said, referring to selective catalytic reduction systems.

Vessels large enough to require more than 1,600 total horsepower are typically big enough to accommodate this larger equipment, Willard added. Even so, he believes the MAN modular SCR system offers many advantages.

“I think MAN’s approach makes the most sense so far,” he said. “With their system, you replace the whole thing when needed like you would with any exhaust silencer versus servicing a system inside the boat.”

Aside from cost, concerns related to adopting Tier 4 engines have primarily focused on space. The SCR systems used by nearly all marine engine makers to reduce nitrogen oxides (NOx) can take up a fair amount of space. They are also heavy and create a lot of heat, each of which requires a new solution.

Finding room for these systems is a much bigger concern on pilot boats than, say, a 90-foot harbor tugboat. McCloy said the pilots did extensive research and considered other engine makers, which had much larger SCR units than what MAN offered. The size and weight of the MAN engines were a factor, he said, but the highly flexible modular SCR system was another benefit.

“Whenever I tell someone about it, I ask if they remember that GI Joe action figure that could turn backwards and was so flexible you could touch its leg with its elbow. It’s kind of like that. They are very configurable,” he said.

Snow & Company delivered a similar 64-foot Camarc launch last spring for the Savannah Pilots, and it will deliver another one shortly. Both have EPA Tier 3 engines. From a construction standpoint, the Tier 4 system adds a layer of complexity, according to Snow & Company Vice President Tim Kolb.

“There are a lot more components that come with the Tier 4 engines, such as the SCR, the DEF tanks, the DEF piping,” he said, referring to diesel exhaust fluid (DEF). “There is more space that it takes up, even though these SCRs are the smallest on the market.”

“The additional components of a Tier 4 exhaust system bring alignment and routing challenges as well as increased equipment volume that must be accommodated,” he added. “Development of detailed 3D models early in the design process paid huge dividends in the successful integration of the exhaust system.”

These lessons and many more, Kolb said, can be applied to future projects that incorporate these systems. •