BlueTEC Texel platform inaugurated by Mayor of Texel

|

|

|

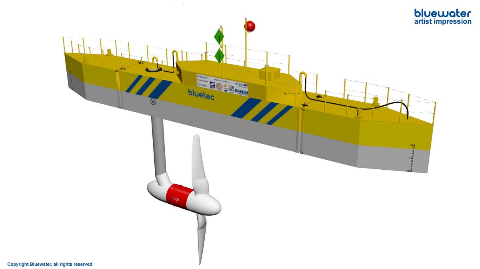

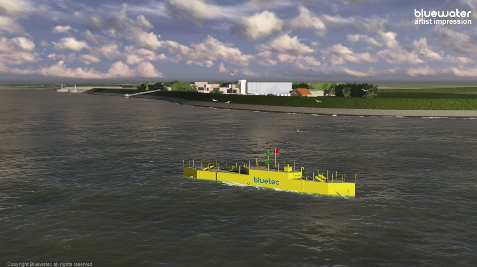

Den Helder; April 9, 2015 – Today the first BlueTEC Tidal Energy platform was formally named by the Mayor of Texel, the Netherlands. The floating platform, which holds tidal turbines below the sea surface, will soon be positioned near the island of Texel – supplying clean electricity to the Dutch grid. This first BlueTEC will serve as a demonstration platform targeted at remote locations world-wide, such as islands in Indonesia, Philippines and the Pacific. It is also the start of further development of higher capacity tidal energy platforms, to be deployed in large farms.

“We are very pleased that we have reached this exciting milestone for our first floating tidal demonstration platform,” says Bluewater’s Head of New Energy Allard van Hoeken at the naming ceremony. Mr. Van Hoeken adds: “It is wonderful to see the Texel tidal energy project come to reality. Today’s ceremony puts us a step closer to our goal of putting an all-in-one tidal energy platform on the market and delivering clean, local and endless energy to the world.”

The coming weeks, the platform will be installed offshore the island of Texel and connected to the Dutch electricity grid – starting its electricity production before summer. It is meant to stay there producing elec-tricity for several years, allowing multiple turbines to be tried out.

This platform is targeted at a worldwide market, it can be shipped as containers and installed anywhere in the world, to provide clean electricity in remote areas and small islands, replacing expensive and polluting diesel generators. An important advantage of tidal energy is its predictability and consistency, bringing stability to local electricity grids.

As all vulnerable electronic equipment is safely housed inside the unit, with easy access from the surface since it floats, inspection for maintenance and repair purposes is a straightforward matter. This makes it a truly unique product. It is also the first time that a complete, integrated tidal system is offered to the market.

Collaborative efforts

The project draws on the specialist skills and experience of an impressive list of partners, many of them having their core business in the offshore oil&gas industry. “This project is realized thanks to the close cooperation between all involved. Everyone has demonstrated huge enthusiasm – it is fantastic to be a part of that,” concludes Mr. Van Hoeken.

Modular benefits

The platform is a development of Damen’s modular barge system – a flexible product that can be put into effect in the construction of a wide range of vessels from dredgers and jetties to ferries and pontoons.

Damen used three standard container-sized modules to construct the Texel platform. The efficiency of containerized transportation combined with uncomplicated assembly means that the platform can be trans-ported and installed anywhere in the world.

ABOUT THE BLUETEC PARTNERS

Bluewater Energy Services

Bluewater’s core business is to design, deliver and operate Floating Production, Storage and Offloading (FPSO) systems and Single Point Mooring (SPM) systems. The New Energy department uses the skills and experience of the core business to develop advanced technology for harvesting clean and sustainable energy, starting with Tidal Energy.

Bluewater’s New Energy department is the initiator and leading partner in the development of the BlueTEC Texel Tidal Project. They started in 2009 with the development of the floating BlueTEC concept.

“Based on our offshore experience, floating platforms offer a breakthrough in tidal energy” says Bluewater’s Head of New Energy, Allard van Hoeken. “The worldwide growth potential for tidal energy is massive. While we starting with small platforms, eventually we eventually want to design, build, own and operate tidal farms that produce as much as 500 MW using 2-3 MW BlueTEC units.”

Allard van Hoeken recently received the first Prince Friso Engineers Award, for his dedication to make with his team the transition from the traditional offshore industry to renewables.

Damen Shipyards Group

Damen Shipyards Group operates 32 ship- and repair yards, employing 8,000 people worldwide. Damen has built more than 5,000 vessels in more than 100 countries and delivers approximately 180 vessels annually to customers worldwide.

Damen’s role in the Texel tidal energy platform stems from its focus on standardisation and modular con-struction which leads to short delivery times, low ‘total cost of ownership’, high resale value and reliable performance. Furthermore, Damen products are based on thorough R&D and proven technology.

“The Texel tidal platform consists of a lot of shipbuilding components and Damen has all the disciplines necessary to put that all together,” says Damen Sales Manager Jelle Meindertsma. “In the future, our series construction will really come to the fore when dealing with tidal generation ‘farms’ with 20 or 30 turbine platforms. There is a lot of potential in the tidal energy market – this prototype is just the beginning.”

Acta Marine

Acta Marine is a worldwide market leader in the operation of coastal and shallow draft workboats. Our company was established in 1970 and today we own and operate over fifty different vessels, which are used for coastal water projects for a large variety of clients. Acta Marine is the innovator of DP Multicats and specializes in cable and pipeline remedial burial projects in coastal and shallow waters. These spe-cialties enable us to offer the best and most effective solutions to our clients in the Dredging & Marine Construction, Oil & Gas and Offshore Wind industry.

Ruben de Vries, Acta Marine Project Manager: “The Dutch Wadden Sea, goes back to the core of our business i.e., operating responsibly in shallow water projects with innovative vessel solutions. The Texel tidal project covers just all of these same core values and Acta Marine is pleased to render its services during the installation phase of the project.”

Tocardo

Tocardo Tidal Turbines is a Dutch company dedicated to delivering the most effective and economical turbines to harvest energy from the world’s oceans and rivers. With four turbines operational in The Neth-erlands, nine turbines under construction (to be installed in 2015) and several projects in the pipeline worldwide, Tocardo is a leader in the tidal power industry.

Tocardo delivers the initial T1 turbine and later in 2015 a T2 turbine for the BlueTEC Texel Tidal project.

Tocardo CEO Hans van Breugel: “We are very pleased with the fruitful cooperation with all the partners and look forward to a successful project and commercial roll-out of the BlueTEC concept. For Tocardo it’s an important milestone as it’s our first floating offshore project.”

SCHOTTEL HYDRO

SCHOTTEL HYDRO offers its services in three segments: hydrokinetic turbines, semi-submerged plat-forms and components, such as turbine hubs and drives. SCHOTTEL HYDRO also includes the British company TidalStream Ltd. (TSL), in which SCHOTTEL holds the majority of shares, and the Canadian company Black Rock Tidal Power (BRTP). SCHOTTEL HYDRO is located in Spay, Germany. A large network of SCHOTTEL sales and service locations ensure customer proximity worldwide.

The SCHOTTEL Instream Turbine (SIT) is a lightweight and yet robust hydrokinetic turbine. The BlueTEC Texel platform will be equipped with one SIT with 4-metre rotor diameter, producing grid-ready electric power in 2015. For 2016 they plan to deploy two SCHOTTEL HYDRO turbines with 4-metre rotor diameter for both tidal flow directions, each producing 62 kW of rated, grid-ready electric power.

While the Texel platform is aimed at remote locations to power villages, cooling facilities, lighting etc. SIT is very versatile and can be implemented in rivers, sea straits and tidal races offshore in jetty, floating or submerged platforms in varying quantities.

TKF

Since its establishment in 1930, TKF has developed from a cable producer to a leading supplier of con-nectivity solutions located in the Netherlands. A broad range of cables, systems and services enables us to provide our customers worldwide with safe and reliable power and data connections for Telecom, Build-ing and Industrial markets. Being part of the technology company TKH Group NV, TKF has access to breakthrough solutions, concepts and technologies.

TKF provided the Texel Tidal project with the complete scope of cable and connectivity solutions for the energy transmission from the platform towards the terminations on the mainland. TKF developed the sub-sea cable, including fiber-optics for communication and data control, the hang-off and bending restrictors and provided the engineering, delivering, installation and assembly of the all the components. From the generator towards linking the network, TKF provided the complete connection.

Laurens Pots from TKF: “This project was of great interest for us because of the expansion of our subsea capabilities with the development of our new subsea plant. Within this project we have developed new offshore competences that we can expand towards our subsea activities in, amongst others, the renewable energy market.”

Vryhof Anchors Vryhof Anchors provides High Holding Power Anchors, engineered products and services to the offshore Marine Renewable Energy and Oil & Gas Industry and can be described as the market leader in mooring solutions. Vryhof has delivered more than 10,000 drag anchors globally since its inception. Vryhof is proud to be part of the Texel Tidal Energy Project and have the possibility of transferring its Oil & Gas field knowledge to the BlueTEC modular tidal energy device. The main target was to design the smallest suitable anchors to maintain the tidal device in place – keeping it as efficient as possible in order to keep the costs to a minimum. “With Vryhof’s suite of anchoring solutions we can moor this tidal en-ergy platform anywhere in the world,” says Vryhof Projects Director Senol Ozmutlu.

The BlueTEC floater is a smart design with its containerised modular form: “Vryhof’s reason for participat-ing in the Texel project is to provide the optimised mooring solution suitable for future farm scale projects,” comments Vryhof Business Development Manager Christophe Limouzin.

Royal NIOZ

The Royal Netherlands Institute for Sea Research is the national oceanographic institute and is one of the institutes of the Netherlands Organisation for Scientific Research (NWO). The mission of Royal NIOZ is to gain and spread scientific knowledge on estuaries, coastal seas and oceans for a better understanding and a sustainable management of our planet.

The role of Royal NIOZ in the Texel Tidal energy project is primarily to perform research into the effects of the platform and turbine on various abiotic factors such as tidal currents, suspended sediment concentra-tion and bathymetry around the platform, using Acoustic Doppler Current Profilers mounted beneath the platform and the NIOZ research vessels RV Navicula and RV Stern. In addition, they will analyse infor-mation about wave structure.

“We are proud to be involved with such a forward-thinking energy generation project,” comments NIOZ director professor Henk Brinkhuis. “The comprehensive data set that we are collecting will be invaluable for future development of worldwide tidal energy programmes.”

Nylacast

Nylacast is a world leader in the design and manufacture of Polymers and Engineered Solutions to the Marine, Gas, Oil and Offshore sectors. Founded and based in Leicester in 1969, Nylacast provides value-added solutions to its partners and innovative technology with significant technical expertise in the engi-neered polymers market and offers a unique total solution proposition in the market place. This end-to-end service comprises material selection, design and engineering consultation, advanced machining, applica-tion testing and service inspection.

Nylacast was invited to form part of the collaboration supplying a ‘trumpet’, which acts as a liner within the mooring system. The Nylacast Liner works to effectively improve the mooring systems due to its high load bearing capability and low friction characteristics.

Tan Ali Sales and Marketing Director: “Nylacast was involved at an early stage in the design and concept of the project and delivered a highly innovative technical solution. Our extensive knowledge of the marine environment and proven track record in our materials technology ensured that our product supported this innovative technology in tidal energy.”

TTC Tidal Testing Centre

Tidal Testing Centre is an international test facility for marine energy systems. It provides high-speed open water facilities in two sluice gates of the Afsluitdijk in the Dutch Wadden Sea.

For the Texel Tidal Energy project, TTC managed the permit process for a new offshore site near the island of Texel. In just under 6 months all permits were obtained.

TTC liaised with all stakeholders about the responsibility and liabilities for operating at such a site. "We have an easily accessible, grid-connected offshore test site at just over an hours drive from Schiphol. We expect to attract many international developers to come and test here in the future," says Peter Scheijgrond, Infrastructure Manager at TTC.

Niron Staal

Niron Staal Amsterdam B.V. is a specialised steel construction and machining company. We are located in the harbour of Amsterdam – thus guaranteeing deep-water access to the North Sea and efficient flight options via Schiphol Airport. The combination of steel construction and machining allows us to operate on large-scale projects such as heavy construction work as well as small-scale contracts that involve accurate machining at extremely low tolerances. Furthermore, we take on everything in between – hence our motto: ‘Experience the perfection’.

The Bluetec Platform was built at Niron Staal in a very short time thanks to our ‘EngineeringSmartScan’, which allowed us to cooperate with engineers from Bluewater and Damen at an early stage. Before and after the fabrication stage, we supervised the construction in order to minimise the production costs and to have the fastest turnaround time.

Niron Staal General Manager Harco Groen: “This platform is an important project for our machine shop and steel construction division as its components are large and complex. From the outside, the BlueTEC platform looks like a simple construction, but inside it is full of innovation and high-tech parts. This project is our gateway to tidal energy.”

Port of Den Helder

“Port of Den Helder is de service haven voor offshore energy industrie. Niet alleen door de gunstige ligging voor de olie en gas exploratie en de centrale ligging tussen de Britse en Nederlandse Windfarms. Voor Bluewater is de ligging van Port of Den Helder ook favoriet voor het opwekken van getijdenenergie, omdat er de hoogste stroomsnelheden worden behaald aan de Nederlandse kust.

Ook de regionale beschikbaarheid van onderzoeks- en opleidingsinstituten is voor deze keuze van belang. De beschikbaarheid van Airport Den Helder en goede treinverbinding met Schiphol spelen ook een be-langrijke rol omdat het een testsite is voor een internationale markt” aldus Piet Hein Kolff van Port of Den Helder.

Van Oord

Van Oord is a leading international contractor specialising in dredging and offshore projects (oil, gas and wind). Its head office is located in Rotterdam, the Netherlands. The company’s expertise ranges from design to execution and it has been involved in such noteworthy projects as Palm Jumeirah in Dubai, the port of Rotterdam’s Maasvlakte 2 expansion, the installation of a Gravity Based Structure Arkutun Dagi in Russia, shallow water pipe lay installation and the construction of several offshore wind farms in the North Sea. For more than 145 years Van Oord is an independent family business that employs about 5,000 professionals worldwide. Its modern fleet consists of more than one hundred vessels and other specialised equipment.

Because of the high current South of the Island Texel, installation of the platform and all of its components will be a challenge. Van Oord contributes with its expert knowledge and experience in the offshore industry to manage the installation of the mooring system, cable and platform in these challenging conditions.

Rick van Vliet, Van Oord’s Project Manager: "The Texel Tidal Project contributes to Van Oord’s sustaina-bility profile and provides Van Oord with the opportunity to be part of a group of pioneering companies in the Renewable Energy industry."