By using sound waves, ultrasonic antifouling can prevent the growth of algae, barnacles and slime on boat hulls and interiors, and can protect sea chests and box coolers as well. The technology has been employed internationally from Europe to Australia, Japan, Chile and the Caribbean, and implemented on commercial, military and recreational vessels. More recently, these systems have caught on with yacht owners in North America.

Fouled, rough hulls can slow boats and increase fuel consumption, and antifouling paints — while effective — can release toxins when a vessel is in the water or when coatings are scraped off in dry dock. Usage of ultrasound has grown following the International Maritime Organization’s ban over a decade ago on organotin in bottom paints, and because of moves to limit copper as an antifouling agent. Ultrasonic systems don’t rely on chemicals that can harm fish and mammals or pollute the air, and they can reduce vessel lift-outs for cleaning.

The cleaning abilities of sound waves have been recognized since before World War II. Starting in the 1950s, sound waves were utilized for this purpose in the food, agriculture, electronics, medical, aircraft and auto industries. While ultrasound’s marine applications have been acknowledged for decades, usage by commercial vessel operators has only gained traction in the past 15 years. To install a system, transducers are mounted inside a vessel’s hull, or on other internal features, along with a control box. Onboard generators or shore sources power the equipment.

“Wherever sea, river or estuary water touches a vessel or its internal equipment, biological organisms are at work, clogging pipework, encrusting the hull and propeller, increasing fuel consumption and requiring expensive remedial work,” said Darren Rowlands, director of NRG Marine Ltd. in the United Kingdom. “Antifouling is therefore an essential preventative measure that all commercial, military or leisure operators use to maintain smooth, fouling-free surfaces to reduce running costs and extend service intervals.”

NRG Marine, launched in 2006, manufactures Sonihull, a range of antifouling systems employing sound waves. “Using ultrasound requires less surface preparation and has less environmental impact than self-polishing and biocidal coatings,” Rowlands said. “There’s no requirement for regular replacement of parts, as with impressed-current systems. Ultrasonic antifouling can keep weeds, barnacles and mussels away without hazardous chemicals, cathodes or paints, (and) with no expensive lift-outs, scraping, high-pressure cleaning or the subsequent disposal of poisonous wastewater.”

|

|

To limit the length of time vessels have to spend out of the water, the Coast Guard has tested Sonihull ultrasonic antifouling systems on patrol boats like the one shown here. |

|

Courtesy NRG Marine |

Impressed current antifouling (ICAF) systems typically use a copper alloy rod to prevent fouling and an aluminum or ferrous alloy rod to reduce corrosion, along with a power unit.

Introduced to the market in 2008, NRG Marine’s Sonihull systems produce multiple pulses of ultrasonic energy in a range of targeted frequencies. These pulses are transmitted through the material to which the transducer is attached, whether that’s the hull, propeller shaft, pipework, box cooler or tank. The systems work on any metal or solid composite material, like glass-reinforced plastic and carbon fiber.

The pulses produce a pattern of alternating positive and negative pressure on the surface of the material, Rowlands said. Microscopic bubbles are created during the negative pressure cycle and are imploded during the positive pressure cycle.

“This microscopic surface agitation has a cleansing effect that destroys algae, the first link in the marine food chain,” Rowlands said. That keeps the surface clean and makes it a much less inviting habitat for larger organisms that feed on algae, preventing a buildup of fouling. The microscopic movement of water also prevents barnacle and mussel larvae from embedding on the surface.

“Our Sonihull systems are already in operation with several coast guards and navies around the world,” Rowlands said. “We’ve also developed technical partnerships with leading builders and propulsion manufacturers who are looking for a better way to keep weeds and barnacles off vessels. We currently have 15 distribution and installation partners around the globe, transforming how commercial, military and leisure craft are dealing with marine fouling issues.”

For commercial users, the most common application of ultrasonic antifouling is protecting sea chests, bucket strainers, box coolers, intakes and piping for dry plate cleaners, said Chiel de Wit of Delta-Sistems BV in the Netherlands. “In smaller vessels, we can also protect the hull,” he said.

|

|

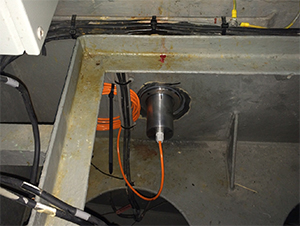

Each antifouling system includes a control unit and cup-like transducers that are mounted to the hull or to the equipment to be protected. |

|

Courtesy U.S. Coast Guard |

In January, Delta-Sistems acquired Shipsonic, a Dutch firm that introduced its ultrasonic antifouling technology in 2006. Shipsonic’s systems use ultrasound to prevent algae and barnacle buildup below a ship’s waterline and on box coolers, ballast tanks, water tanks and fuel tanks.

“Our biggest customer sector is the offshore industry, especially in Norway,” de Wit said. “Offshore maintenance and supply vessels have lots of machinery on board, hence they need a lot of cooling capacity. They have lots of box coolers.”

Ultrasonic antifouling has three big advantages, de Wit said. “These systems are dry-installed and maintained, so there’s no need to dry dock the ship,” he said. “They are cheap compared with conventional copper-anode technology. And ultrasonic antifouling technology is green, with zero impact on the environment.”

De Wit said ultrasound’s use in various cleaning applications is widespread, but it remains limited in marine antifouling for two reasons: reliability and effectiveness. “We think we have the biggest, purely technical challenges under control, however,” he said. “We’re now able to produce systems that are robust in the harsh conditions of the commercial marine environment, while also putting out the high wattage needed for the transducers to be effective. These systems withstand high temperatures, such as in the engine room, and they withstand big temperature changes and constant vibrations.”

“Transducers typically have a peak power of 100 watts or more, and our biggest system is eight times 100 watts,” de Wit said. “That results in pretty high currents and temperatures in the system.”

All producers of ultrasonic antifouling systems continue to face a lack of consistency in the technology’s effectiveness, according to de Wit. Comparable applications in comparable environments still produce different results.

“We’ve run tests on one ship, with two identical systems on two similar sea chests, mirrored starboard and port, with unacceptable and as-yet-unexplained differences in results,” he said.

Shipsonic is entering a partnership with the Royal Netherlands Institute for Sea Research (NIOZ) to design and implement a research program to tackle issues related to the technology’s effectiveness.

“Once we’re able to offer a 100-percent-reliable fouling solution, we feel the market will grow exponentially,” de Wit said. “Shipsonic is working toward a complete new take, in which we’re moving from selling hardware to implementing solutions. The research program with the NIOZ will be a cornerstone for realizing this vision.”

Meanwhile, the company is participating in an experiment in Norway to keep net cages clean for the salmon industry.

Ultrasound devices from Belgium-based Harsonic are used mainly to avoid fouling on cooling systems and strainers aboard commercial vessels, said company CEO Mieke Harteel. “Ours are the only ones on the market that work with a combination of two technologies: ultrasound and proprietary HS technology. HS technology is our own invention.” He declined to go into detail about it.

With more than 25 years in water treatment, Harsonic specializes in the removal of biofilm in several applications without using chemicals.

|

|

Shipsonic’s ultrasonic antifouling systems are used most often to protect sea chests, bucket strainers, box coolers and intakes. The mounted transducers are powered by ventilated units, shown above. |

|

Courtesy Delta-Sistems |

“Customers often replace their impressed current antifouling systems with Harsonic because their ICAF systems aren’t adequate against fouling,” Harteel said. “And since ultrasound doesn’t pollute, Harsonic is a full ecological solution that doesn’t harm our oceans.”

In addition to selling devices for ultrasonically cleaning vessel hulls, propellers, gas oil tanks, water tanks and box coolers, Harsonic produces equipment for cleaning cooling towers and heat exchangers, industrial tanks and filters, pipelines, agricultural tanks and open-water storage.

“We’re located around the world in 24 countries,” Harteel said. “We aren’t in the United States yet.”

In April 2016, Australia-based Aqualuma LED Lighting, with an office in Florida, introduced its ultrasonic antifouling system. “The system, which is scaleable for any size vessel and hull composition — GRP fiberglass, carbon fiber, Kevlar, steel or aluminum — outputs a refined automated program of short, ultrasonic-wave burst signals through ultrasonic transducers,” the company said.

Aqualuma’s antifouling technology offers protection in all climates for hulls, running gears, props, rudders, IPS drives, stern drives, sea chests, seawater piping, sea strainers, thrusters and stabilizers.

“The system has built-in smarts for reduced power consumption and low-battery protection,” according to the company.

|

|

A mounted transducer on an antifouling system. |

|

Courtesy Delta-Sistems |

Aqualuma specializes in the production of underwater, dock, pathway and outdoor light-emitting diode, or LED, lights.

Environmental legislation has been a driving force for antifouling know-how and could lead to the further adoption of ultrasound systems. One of the top related issues currently facing ship operators is the IMO’s Ballast Water Management Convention, which comes into force in September.

“The BWMC targets the transport of invasive aquatic species through ships’ ballast water. However, the IMO has indicated already that the transport of invasive species, attached as fouling on ships’ hulls, is a much bigger problem,” Rowlands said.

The danger of harmful metallic compounds in antifouling paints has pushed the industry to develop new less-toxic biocide chemicals, self-polishing paints and suppressed-current and ultrasound technologies, Rowlands said, and he expects that trend to continue.

“Between the bookends of legislation and profit margins, shipowners will always be looking for antifouling solutions that combine lower environmental impacts with lower operating costs,” he said.