As far as the Mia S. captain and pilot knew, engineering crew had resolved the engine problems bedeviling their loaded bulk carrier sailing outbound on the Mississippi River near New Orleans. But less than 20 minutes after full power was restored, the ship abruptly slowed yet again.

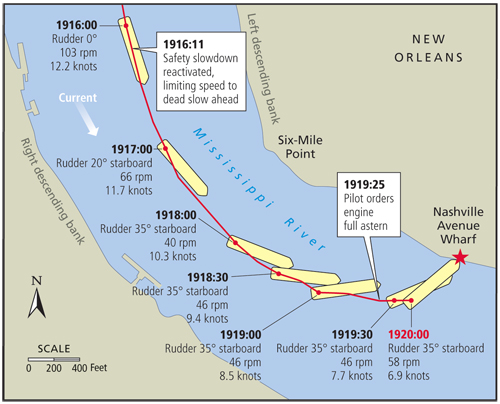

The 623-foot bulker lost speed and swung to port in the following current. Rudder orders to starboard didn’t stop its drift toward the left bank, and Mia S. slammed bow-first into the Nashville Avenue Wharf at 1920 on Aug. 18, 2017.

The National Transportation Safety Board (NTSB) zeroed in on the chief engineer’s call with the captain shortly before the incident suggesting the engine problem had been fixed. In reality, additional engine slowdowns were likely.

The NTSB determined “the chief engineer’s poor communication to the master regarding the potential for additional protective engine slowdowns” was a leading cause for the incident.

Engineering crew aboard Mia S. identified a stuck non-return valve preventing fuel from reaching the No. 2 engine cylinder as the cause for the automatic engine “safety shutdowns.” Some crew believed low-sulfur fuel might have contributed to the problem with the aging components.

Mia S. left a grain terminal at mile marker 120 on the Lower Mississippi at about 1700 on the day of the accident. The bulker, carrying soybeans for South America, recorded the first slowdown eight minutes after dismissing the assist tugs. The engine slowed to dead slow ahead, or 45 rpm. Full ahead is 115 rpm.

Crew agreed to anchor to assess the problem, but the nearest deep-draft anchorage was full. The New Orleans-Baton Rouge Steamship Pilots Association (NOBRA) pilot conning the ship opted for another anchorage 40 miles downriver in Belle Chasse, La. The pilot proposed keeping the engines in dead slow ahead for the voyage, and also arranged for an assist tug to come alongside.

Sporadic propulsion issues persisted for another hour as Mia S. continued toward Belle Chasse. Engine speeds varied between 45 and 70 rpm during this time. Engineering crew made a temporary fix at about 1850.

“With the Mia S.’s speed at 7 knots and engine at 45 rpm, the chief engineer informed the master that the issue with the fuel pump was resolved and thereby full speed could be attained. Based on that report, the pilot ordered full ahead at 1857,” the NTSB report said.

|

|

The bulk carrier’s track line in the four minutes preceding the accident shows the change in the vessel’s heading and speed following a “protective engine slowdown” caused by a stuck valve. |

|

NTSB/Pat Rossi illustration |

At 1916, an alarm registering high exhaust temperatures activated as the ship approached the 108-degree bend at mile marker 101. The engine dropped from 103 rpm to 40 rpm in two minutes. The pilot ordered the rudder hard to starboard to arrest the ship’s drift toward the left descending bank, but the maneuver was not successful.

Mia S., registered in Antigua and Barbuda, struck the Nashville Avenue Wharf at about 7 knots. The impact left a V-shaped impression in the structure, and the ship sustained a massive gash in its bow above the waterline. Property damage totaled an estimated $2 million.

Mia S. is equipped with a slow-speed, direct-drive MAN B&W engine generating 12,713 horsepower. The engine control system monitors exhaust temperatures in each cylinder and triggers a “safety shutdown” when the differential between cylinders exceeds 122 degrees Fahrenheit, the report said. The system is designed to protect cylinders from overheating and damaging the engine.

The NTSB did not specify the reason the non-return valve stuck. The problematic valve on the No. 2 cylinder had nearly 7,200 hours of service, and replacement was scheduled for 8,000 hours. The ship experienced a similar problem with the fuel injection pump for the No. 5 cylinder while transiting downriver to the Belle Chasse anchorage on the day after the incident.

All six non-return valves on the engine were replaced while at anchor, the report said. Testing conducted a week after the accident found no problems.

Low-sulfur fuel is used under international regulations when ships come within 200 miles of land. Vessel operators and regulators around the world have identified potential engine problems stemming from the change from standard marine diesel to low-sulfur fuel.

“Considering that sulfur improves the lubricating properties of the fuel, the lack of sulfur in the fuel oil may have caused the non-return valve to seize and thereby prevented fuel from injecting into the cylinders,” the report said.

Attempts to reach Bogota-based ship operator Navesco S.A. were not successful. A spokesman for the NOBRA pilots did not respond to an inquiry about the NTSB findings.