(SANDNES, Norway) — Optimarin Ballast Systems (OBS) have gained approval from the United States Coast Guard (USCG) slashing their required holding time from 72 to just 24 hours for all salinities. The certification ensures the systems are optimized for short-sea shipping routes in the U.S., as the time between ballast water treatment (BWT) and de-ballasting is cut dramatically.

USCG requires a holding time post-treatment for ultraviolet (UV) systems. This is to ensure all cells are inactive before testing. However, with increased UV doses, such as those provided by OBS’ 35-kW lamps, the holding time can be reduced, thus enabling greater vessel flexibility.

“This is another endorsement of OBS by the USCG, which will itself be utilizing our technology in its new offshore patrol cutter program,” said Optimarin CEO Tore Andersen. “Our system was the first to gain full USCG approval and now it boasts the current minimum required holding time for UV-based solutions. This will have a major impact for shipowners trading between domestic ports in the U.S.”

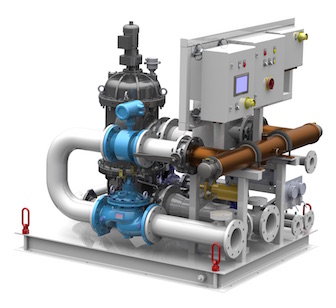

Systems with three-day holding times are required to wait for that duration before discharging treated water at port – meaning vessels may have to anchor and interrupt operations if conducting short voyages. The efficacy of the 50 to 3,000 cubic meters per hour OBS, however, ensures short turnarounds and optimal efficiency for shipowners trading in North American waters.

“It is our objective to make life as simple as possible for owners and operators,” Andersen explains. “We have tailored our system to be easy – to install, operate, maintain, retrofit and, crucially, to rely on. It meets the most stringent regulatory standards in the world, with a track record of proven performance, and now helps enable maximum flexibility and availability for customers trading in this demanding environment."

At present, USCG continues to utilize the CMFDA/FDA staining test methodology, which requires disruption to the membranes of organic cells carried in ballast water. Even though premium UV-based systems, such as OBS, eliminate all organisms instantly membranes may not be immediately disrupted, leading to the holding time requirement.

Optimarin’s proven success in the market, with over 500 OBS installed and operational, of which approximately 250 are retrofits, promises to reach a new level in 2019. The BWT specialist’s order book is currently five times the size it was at this point in 2018, with revenues expected to double year-on-year. More than 700 of its systems have now been sold.

Alongside its full IMO and USCG compliance, Optimarin has certification from a comprehensive range of classification organizations, including ABS, BV, DNV-GL, LR & MLIT Japan. Current customers include Royal Caribbean International, Fednav, GulfMark, Hapag Lloyd, Matson Navigation, McDermott, the Danish Navy, MOL, Seatruck, Technip, and the Royal Netherlands Navy, amongst others.

For more information, visit www.optimarin.com.