During a summer-like April day in Seattle, Dunlap Towing crews performed finishing touches on a new tractor tug bound for the demanding waters off Alaska’s Aleutian Islands.

Hansen Boat Company of Everett, Wash., built Gretchen Dunlap, which was scheduled to begin sea trials in late April before heading to work in Dutch Harbor. There, it will replace the 20-year-old harbor tug James Dunlap.

At nearly 7,000 hp, Gretchen Dunlap is more powerful and more versatile than its predecessor, according to Gordon Taylor, Dunlap Towing’s vice president of marine operations.

“It has almost twice the bollard pull, which will give a broader weather window for the ship’s arrival (and) departure, creating a larger window of opportunity for the ships calling on the Port of Dutch Harbor,” Taylor said. “It seems like the wind is blowing there all the time.”

|

|

Gordon Taylor, Dunlap Towing’s vice president of marine operations aboard the 101-foot tug. |

With ships getting larger, it takes more bollard pull to handle the jobs, he added.

“James Dunlap is pushing 20 years old and needs to move into a different environment,” he said.

Like its predecessor, Gretchen is 101 feet long. But at 42 feet wide and 20.5 feet deep, the new tug is wider and deeper than the existing Dutch Harbor boat. The new tug is also more powerful, with 6,772 hp compared to 4,300 hp.

The design for Gretchen Dunlap evolved from James Dunlap, said naval architect Michael Whalen of the Seattle firm Hockema & Whalen Associates.

“The goal was to start with the original boat and improve things we saw as being worth improving and to increase the horsepower significantly,” Whalen said.

|

|

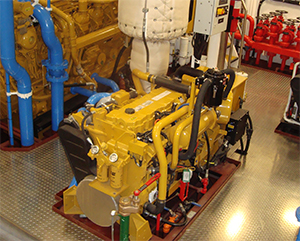

Chief engineer Scott Wilson with one of two Caterpillar 3516C main engines, each producing 3,386 hp. |

Gretchen is powered by two Caterpillar 3516C engines running at 1800 rpm driving Rolls-Royce US 255/P30 FP z-drives. The new boat is expected to have 90-tons of bollard pull.

“There is no reduction gear,” Whalen explained. “We are using Centa composite lightweight shafting running directly from the engines to the ASD unit input. Two people can pick up the entire shaft.”

James Dunlap was designed to work in Dutch Harbor as a ship handling and assist/rescue tug. Gretchen Dunlap will perform similar work handling large ships operated by APL, Maersk and Matson. The new tug also is capable of barge handling and towing.

Working in Dutch Harbor, tugs need plenty of cushioning around the hull, Taylor explained. Schuyler Companies fendering provides that protection on the bow and stern. A large cylindrical fender around the bow adds to forward protection and aircraft tires are attached along the side of the vessel.

|

|

Auxiliary power aboard Gretchen Dunlap comes from a Caterpillar C9 engine. |

The new boat also has a reconfigured plumb bow allowing it to push low freeboard barges and vessels, with bow fendering carried low to the waterline.

“The cylindrical fender on the bow is better for absorbing energy and better for handling vessels with flared sides,” Whalen said.

On deck, the tug has a Markey DEPCF-52 hawser winch on the bow with Markey “Render/Recover” tension line control for tethered operations. The winch automatically adjusts scope to maintain preset line tension. The stern winch is a 75-hp TES-40 electric hawser winch.

“In escort mode, the tug works off the bow hawser run through the bow staple to the ship. The tug has the ability to ‘shear’ off at an angle so that it can increase drag and develop the maximum braking force. In order to get an ABS escort notation, you have to demonstrate that the boat has adequate stability for the maximum escort design speed in that operation,” Whalen added.

|

|

Rick Hansen of Hansen Boat Company, which built Gretchen Dunlap at its Everett, Wash., yard. |

Both winches are powered by two Caterpillar C9 250-kW auxiliary engines in the engine room, which provide electrical power. The vessel also is outfitted with a Caterpillar 76-kW hotel set for when the vessel is tied up.

In the engine room, ventilation intakes are polished aluminum with the engine room rails are stainless steel as on the rest of the tug.

In planning the engine room design, Taylor said he had different systems clearly separated from each other. For instance, the electrical panel is all on the port-side forward bulkhead of the engine room and the water systems are on the starboard side.

“Everything is advanced on this boat,” Taylor said, showing the electronic control panel to the hydraulic control system that manages the steering through the Rolls-Royce z-drives. “Everything is more sophisticated than on the old boats. The engineer’s best friend is his laptop.”

Up top in the pilothouse, the master has 360-degree visibility, plus overhead windows along the top edge of the wheelhouse giving a view of ships above.

|

|

The galley aboard Gretchen Dunlap features stainless steel appliances and fine wood cabinets. |

The interior of the pilothouse is finely finished in yacht-grade wood installed by the Hansen Boat Company under the direction of Rick Hansen. The electronic navigation equipment — a mix of Furuno and Simrad — is laid out in a convenient horseshoe shape at the operator’s station.

Other improvements over James Dunlap include substantially more comfortable crew quarters. The accommodation is for eight crew in five staterooms. There are three two-person staterooms below deck, along with an engineer’s stateroom. The master’s stateroom is located on the main deck.

“That is similar to the other boat, but we added one stateroom and increased the size of all the accommodations,” Whalen said. “The previous boat had a relatively small deckhouse so that there would be no issues with ship clearance, but one of the complaints was that the crew preferred to have a little more space.”

Another improvement for crew comfort is the addition of a lot more insulation in Gretchen Dunlap, reducing vibration. There is also a Norac floating floor system in the deckhouse and two layers of mineral wool to dampen noise.

“We have more insulation in the engine room, have isolation mounts for all the engines, along with stanchions in the engine room so they don’t transfer the vibration up to the deck,” Whalen said.

|

|

The pilothouse features Furuno and Simrad electronics and navigation equipment. |

For steering, Gretchen Dunlap does not have the traditional wheel and throttle system. Instead, the z-drives do the steering.

The control for the thruster is a dial that they can rotate 360 degrees and the thrust direction will track how the vessel rotates. There is a thumb-controlled lever on top of the dial to control the throttle.

“With each hand you can control the thrusters with speed and direction,” Whalen said. “They are pretty interesting to operate. They can be running full speed ahead, and rotate it 180 degrees and come to a stop, then quickly go in the opposite direction.”

Gretchen Dunlap is classed by ABS and will have an American Bureau of Shipping escort notation.

Delivery was expected soon after successful sea trials. The boat’s crew is ready and waiting for her arrival. Chief engineer Scott Wilson, a nine-year Dunlap employee and one of many tugboat men in his family, looks forward to working on Gretchen Dunlap.

“The engine room is really well planned out,” he said. “We’ve got 7,000 horsepower to work with. I’m pretty excited.”