(SOMERSET, Mass.) – The Pilots’ Association for the Bay and River Delaware has ordered another pilot boat from Gladding-Hearn Shipbuilding. It will be the association’s fourth Chesapeake-class launch and 11th pilot boat built by the shipyard since 1957. Delivery of the new vessel is scheduled for 2024.

Since the Chesapeake class was introduced by Gladding-Hearn in 2003, 28 have been delivered or are under construction for 15 pilot associations throughout the United States.

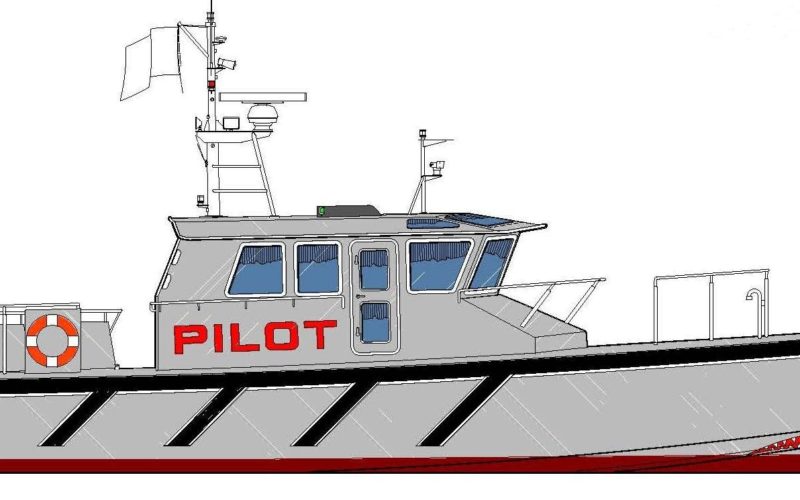

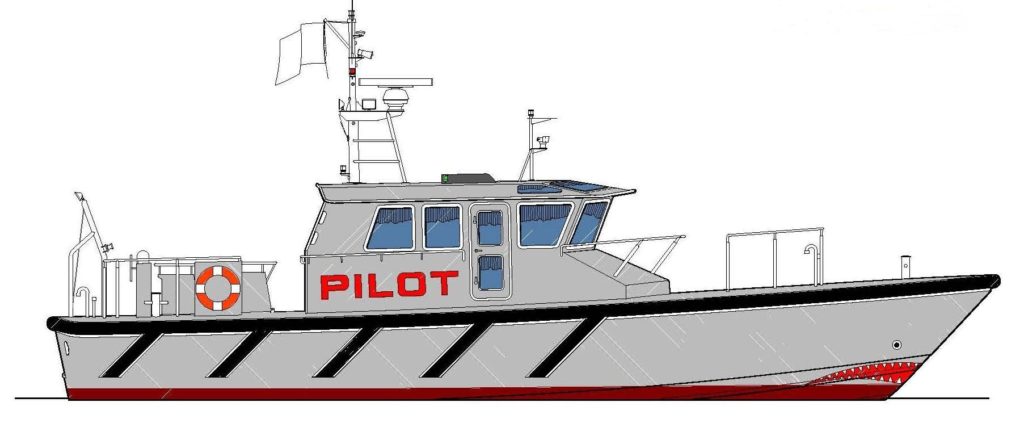

With a deep-V hull designed by Ray Hunt Design, the new all-aluminum launch measures 53.6 feet overall, with a 17.8-inch beam and a 4.9-foot draft. The boat will be powered by twin Volvo Penta D16 diesel engines, each rated for 651 hp at 1,800 rpm. Top speed will reach over 25 knots.

The engines will turn five-blade Bruntons propellers via ZF 500-1-A gearboxes. A Humphree interceptor trim control system, with its automatic trim optimization, will be installed at the transom.

The vessel’s wheelhouse, with a small trunk, will be installed amidships on a flush deck. It is designed with electrically-heated, forward-leaning front and side windows for deicing and four tinted windows on the roof. The wheelhouse has the helm station on center with the Volvo Penta EVC electronic control system and a luggage rack forward.

Aft of the helm station are four Stidd reclining seats and another luggage rack. The forecastle includes an upholstered settee and a hanging locker for exposure suits.

The decks and exterior handrails will be heated to minimize ice formation from flying spray.

A three-zone hydronic cabin, deck heat, and handrail heating system will be installed to circulate heated water through tubes fastened below the main deck, handrails and through three fan-coil units, two in the wheelhouse and one in the forecastle. Treated water will be heated by a 120,000-BTU Espar Hydronic 35 diesel-fired “boiler” and main engine waste heat. An auxiliary heater will be installed in the wheelhouse to heat the vessel while on shore power.

A control station will be located at the transom. A rotating pipe davit will be welded to the deck at the forward end of the rescue recess in the boat’s transom. A self-tailing, two-speed manual winch will be mounted, along with a Naiad Dynamics MateSaver rescue noose, to aid in retrieving a pilot.

– Gladding-Hearn Shipbuilding