Sea Change charts course toward zero-emission propulsion

The world’s first hydrogen-powered ferry could soon enter service in San Francisco, offering a new path for operators looking to eliminate vessel emissions altogether.

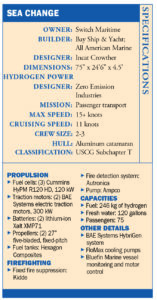

All American Marine completed the 75-foot Sea Change for Switch Maritime earlier this year at its Bellingham, Wash., shipyard. Incat Crowther designed the 75-passenger aluminum catamaran developed with numerous partners across the maritime industry.

All American Marine completed the 75-foot Sea Change for Switch Maritime earlier this year at its Bellingham, Wash., shipyard. Incat Crowther designed the 75-passenger aluminum catamaran developed with numerous partners across the maritime industry.

San Francisco’s Water Emergency Transportation Authority (WETA) has authorized a six-month demonstration project that would have Sea Change operate a short-hop route between Pier 41 and the Ferry Building. Blue & Gold Fleet, whose crews run WETA ferries, is slated to operate the ferry during that period.

As of Sept. 15, the vessel remained in Bellingham. A WETA spokesman said in September that final details about the demonstration project are still being worked out.

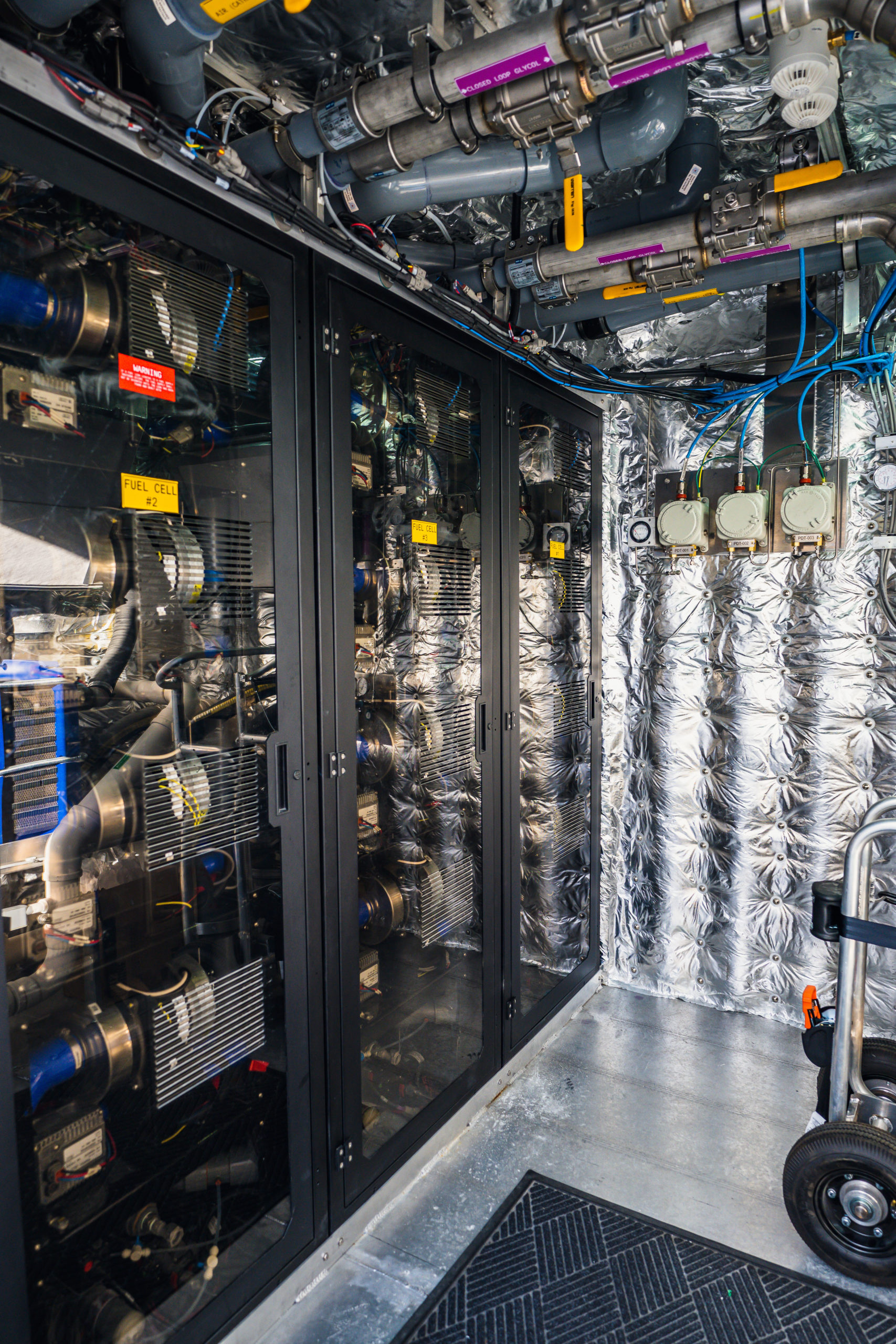

The propulsion system on Sea Change is unlike any other ferry in the world. It consists of 12 Cummins Hydrogenics hydrogen fuel cells that create electricity for two 300-kW (402 hp) BAE Systems electric motors. Battery banks in each hull store 100 kilowatt-hours of electrical power that assist with propulsion. There are no diesel engines on board, making it a true zero-emission vessel.

“I am really proud of it,” said Joe Pratt, CEO of Zero Emission Industries, which designed the propulsion system and has been involved since the project was conceived almost five years ago.

“I have talked to people from all around the world who have heard of this vessel and watched its progress and are waiting for it to get on the water,” he continued. “The impact it has had already through development and sea trials has been more than anything we could have imagined.”

Tom Escher, owner of Red and White Fleet in San Francisco, conceived the idea for a ferry powered by hydrogen fuel cells in the early 2010s. Pratt, then at Sandia National Labs, conducted a study with Lennie Klebanoff that proved that such a vessel was technically possible.

Just as importantly, Pratt said, the study showed there were no outstanding safety issues or “regulatory showstoppers” that would substantially threaten development of hydrogen vessels.

Armed with the knowledge that hydrogen is a viable maritime fuel, Pratt and other stakeholders pitched the concept to the California Air Resources Board, which in 2018 awarded a $3 million grant to support the project, in addition to $2.5 million from other project partners. That same year, Pratt launched the company that became Zero Emission Industries, which is currently producing marine-specific hydrogen fuel cell solutions. In September, Zero Emission Industries announced new investments from Chevron and Crowley.

Bay Ship & Yacht in Alameda, Calif., began construction on the hull in 2018. The following year, Zero Emission Industries sold the vessel to Switch Maritime, which in 2020 moved construction to All American Marine. The vessel was effectively complete last fall, and U.S. Coast Guard regulatory approvals came earlier this year.

Ron Wille, president and COO of All American Marine, said the hybrid power management system on Sea Change is similar to Enhydra and Waterman, hybrid-electric passenger vessels the shipyard built in recent years for Red and White Fleet and Kitsap Transit, respectively. All three use the BAE HybriGen system.

“The backbone of those systems is the same on all three boats,” Wille said in a recent interview. “What we have done with Sea Change is capitalize on our experience on those first two boats.”

Hydrogen fuel cells work by separately reacting hydrogen and oxygen using platinum catalysts. The ensuing chemical reactions create electricity that can be used for propulsion. That reaction is reminiscent of a battery, albeit one that does not need recharging, Wille said.

Sea Change uses lithium-ion batteries in the hulls similarly to a hybrid vehicle. In periods of low power demand, the vessel can run entirely on batteries, while at cruise speed the fuel cells provide power for the electric motors. In short periods of rapid demand, batteries and fuel cells work together for extra power.

The BAE HybriGen system is designed to integrate the fuel cells, the lithium-ion batteries and the hotel power demands into a single system. It also can send power back to the batteries when the fuel cells are generating more power than the vessel needs for propulsion.

“Our technology is able to sense how much power is being called for and decide what is the best source to get that power from,” Joe Hudspeth, BAE’s business development director for global marine, said in a recent interview.

The system is designed to operate seamlessly, with little or no intervention from the operator. “While there is a lot of high tech happening in the background, the captain can focus on driving the vessels,” Hudspeth said.

Hydrogen fuel cells are new in the maritime industry, but they have been used in vehicle transportation for some time. There are numerous hydrogen fuel cell buses operating in places around the U.S., and Toyota and Hyundai sell automobiles powered by hydrogen fuel cells. There are at least 50 retail hydrogen fueling stations operating in California alone.

The Cummins Hydrogenics fuel cells are stored in a compartment aft of the main passenger cabin. It consists of 12 30-kW fuel cells that are stacked together into a single system generating 360 kW, or 482 hp. Each cell is roughly the size of a carry-on suitcase.

Each catamaran hull has an identical, independent propulsion system. The Xalt Energy battery banks are located roughly amidships, forward of the BAE 300-kW traction motors that turn each shaft. Each hull also has a host of equipment and components that facilitate the HybriGen system. There are no reduction gears or main engines, and no oils to carry, helping to reduce overall operating costs.

Gaseous hydrogen is stored in composite tanks supplied by Hexagon Composites above the main deck, which can collectively hold about 250 kilograms of the gas. That capacity is enough to travel around 100 nautical miles, Pratt said, depending on the speed of travel.

Pratt acknowledges most people aren’t familiar with hydrogen. And those who are often associate it with destruction, such as the Hindenburg disaster or the hydrogen bomb. He believes educating people about the gas will help encourage broader adoption across different modes of transportation.

First, hydrogen is 14 times lighter than air, making it by far the lightest known element on Earth. That is precisely why the storage tanks are located on Sea Change’s upper deck. Any leak, no matter how unlikely, would cause hydrogen to float upward at 45 mph away from the vessel and any potential ignition sources.

“Hydrogen itself is not a problem. Hydrogen and a spark is a problem,” he said. “We followed codes around hazardous areas and classified electrical components and we have eliminated that problem so that it is no longer a safety issue. If hydrogen leaks out, it is a simply an issue of lost dollars.”

Hydrogen is also more energy dense than diesel. One kilogram (2.2 pounds) contains as much energy as a gallon of diesel, and there are no emissions when used to generate electricity in a fuel cell. The lone byproducts are heat and water.

The United States has abundant hydrogen supplies, often as a byproduct of the petrochemical industry. So-called “green hydrogen” can be made through electrolysis. The process is energy intensive, but can be done using surplus electricity, including that created by massive hydropower dams in the Pacific Northwest.

There are numerous safety measures built into the vessel, particularly around fire safety. One is a vent system that allows all hydrogen in the tanks to be released from a 30-foot boom on the aft deck within a minute or two. Another is the Kidde fire suppression system in each hull.

“If you look at these holistically, there is a very strong case that hydrogen as it is implemented today is safer than diesel,” Pratt said, pointing to frequent engine room fires on diesel-powered vessels and challenges fighting fires involving lithium-ion batteries.

Sea Change was built as a demonstration vessel and outfitted in a way that was meant to gain regulatory approval. Some of those choices came at the expense of performance. WETA projects Sea Change will operate at 11 knots for only eight hours a day during the six-month trial period. Its top speed is closer to 15 knots, although efforts continue to derive more speed from the vessel.

Pace Ralli, the founder and CEO of Switch Maritime, acknowledged earlier this year that it wants to build a fleet of hydrogen-powered passenger vessels. It also expects data and lessons gleaned from the Sea Change project will improve the performance of future vessels. That data will be shared with Sandia Labs, along with other partners.

“Building bigger and faster vessels requires more capital. We want to start small so it scales nicely so we can build bigger,” he told our sister magazine, Pacific Maritime, earlier this year.

“Building bigger and faster vessels requires more capital. We want to start small so it scales nicely so we can build bigger,” he told our sister magazine, Pacific Maritime, earlier this year.

“Hopefully we’ll be able to build out the green hydrogen supply chain,” Ralli said. Meanwhile, he believes it’s important to invest in the vessel technology so it’s ready. “I think the Sea Change is going to live up to its name in that it’s going to be a catalyst.”

Ralli isn’t the only one eagerly waiting for Sea Change to enter service. Pratt said getting the vessel into service signals a major milestone for the industry and one that should influence wider adoption. He expects the vessel will show, once and for all, that a hydrogen-powered ferry can operate safely, can pass regulatory muster and can build confidence among riders.

“It is checking every box with authority, and it proves this is possible to do,” Pratt said. “In a lot of people’s eyes that was a big question mark.” •

Additional reporting by Pacific Maritime’s Norris Comer.