Designing environmentally friendly ships and converting existing vessels requires a major multidisciplinary approach, involving the extensive expertise of naval architects, designers, engineers, vessel operators, equipment suppliers, and other stakeholders.

It seems everything is on the table when it comes to green ship design, including fuel efficiency, emissions reduction, and the use of sustainable materials. The common thread is the goal of reaching net-zero vessel operations by 2050 woven by international bodies such as DNV Maritime’s Carbon Intensity Indicator (CII) rating system and the International Maritime Organization.

The CII measures a ship’s energy efficiency and is given in grams of CO2 emitted per cargo-carrying capacity and nautical mile.

According to DNV Maritime, the first year of the attained annual operational CII verification is 2024 for vessel operations in calendar year 2023. Based on their performance, vessels will be graded with an environmental rating of A for ‘major superior,’ B for ‘minor superior,’ C for ‘moderate,’ D for ‘minor inferior,’ or E for ‘inferior performance’ levels. The rating thresholds will become increasingly stringent through 2030.

During a vessel’s design phase, naval architects and designers collaborate with various stakeholders, including shipowners, operators, and regulatory bodies ensuring that the final design meets the specific needs and requirements of the vessel owner/operator.

Global shipping currently accounts for nearly 3 percent of total global greenhouse gas emissions with the IMO instituting increasingly strict regulations on emissions for both new-builds and those vessels already in service.

Altering vessels currently in operation to accommodate environmentally friendly technologies is an involved process that can vary widely depending on the ship’s size, age, and structural characteristics.

Most often, it involves the retrofit of the ship with more ‘green, efficient’ engines, upgrading propulsion and waste management systems, and improving energy efficiency through hull modifications – all in compliance with relevant regulations and standards.

All this puts increasing pressure on naval architects to meet new, more stringent ship design requirements.

“Between the Environmental Protection Agency, the EU, the IMO, and China, there are various international standards depending where you are in the world that all have the same goals, but regulate things slightly differently and you have to be an expert to stay up to date with the nuances of each regulatory body’s rules,” states Harrison Brann, P.E., engineering manager at The Shearer Group, the Houston-based naval architecture and marine services firm.

The EPA’s Tier requirements, for example, “certainly play a significant role in vessel design,” he adds. “In general, the EPA is stricter than the IMO, but we see that most operators have a desire to avoid large and expensive Tier 4 engines with either EGR or Urea SCR systems.”

To get around using Tier 4 engines, “We would instead use multiple smaller Tier 3 engines to obtain the cumulative horsepower required. Fitting more engines into a hull certainly has its own design challenges, but it also streamlines the owners maintenance and overhaul programs by only have one type of engine on board versus having 2 Tier 4 prime movers and 2 or more smaller house gensets,” says Brann. “The electrification of a vessel’s propulsion and power grid, which we’re seeing a big push towards, allows for the use of combined Tier 3 gensets which have the added benefit of being able to operate at a constant RPM to further improve fuel efficiency.”

The desire to circumvent the incorporation of Tier 4 power into a vessel design is a serious driver in new design contracts as there are situations where it’s just not reasonable to avoid Tier 4 power options, but a case can be made for multiple Tier 3 engines,” he concludes.

Trends in Design

Digitalization and artificial intelligence will continue to play an increasingly significant role in designing new vessels, along with other major trends, says Munich, Germany-based Siemens AG.

“By moving away from traditional design tools and adopting state-of-the art digital methods, such as generative design, intelligent design exploration and optimization. Naval architects can be freed of traditional design constraints to engineer innovation and maximize performance with green ship technology,” the company said, identifying several “key drivers impacting green efficient ship design,” including:

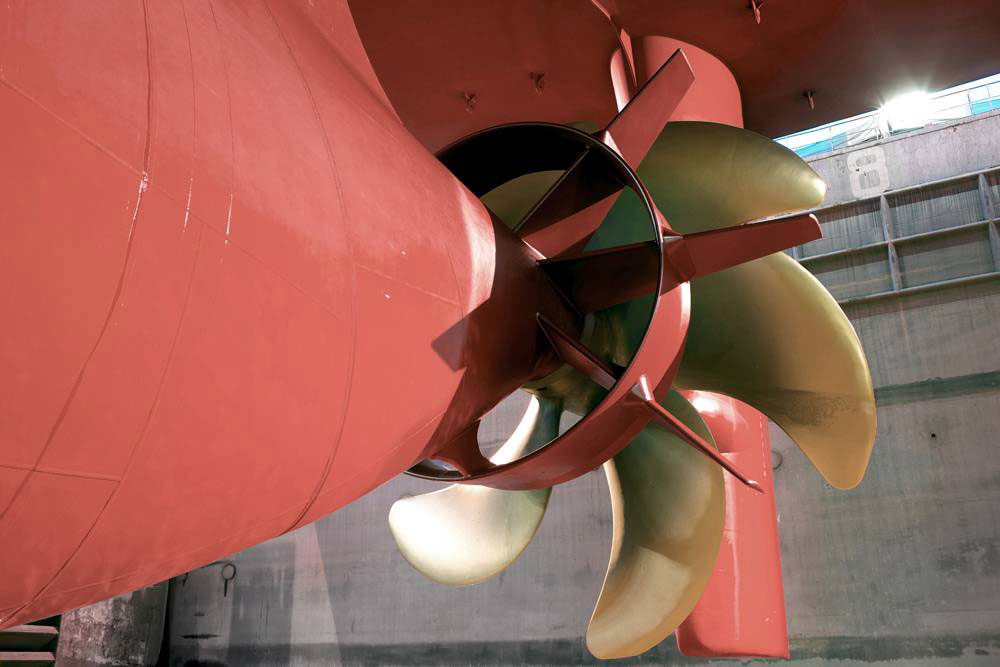

Improving vessel efficiency – “Ship performance is largely driven by vessel efficiency. Naval architects are increasingly looking to optimize the entire propulsion line to achieve maximum efficiency.”

Changing shipping patterns – “Following new routes that avoid contact with fragile ecosystems and at-risk species will go a long way to become more eco-friendly. However, using new routes impacts how new ships are designed and built because they need to operate efficiently along these different routes.”

Lifecycle cost management – “Naval architects need to look at the potential costs throughout the entire ship lifecycle to help owners manage expenses while building an efficient ship.”

Design Developments

RINA, the international classification society, recently approved, in principle, a green retrofit “package solution” designed by Netherlands-based Aurelia in partnership with Econowind, Wattlab and Vertom, which aims at total compliance with CII’s CO2 reduction targets.

According to Aurelia, the retrofit package incorporates rigid sails, solar panels, batteries, optimized weather-routing, and a smart decision support system developed by Hydrographic and Marine Consultants (HMC) to reduce the emissions of “almost any kind of vessel.”

The project has two investment steps for shipowners looking to comply with the CII index.

The first involves the installation of Solar Flatrack technology, batteries, and SafePlan software developed by HMC – a combination of technologies to reduce the hours in service of the auxiliary engines with surplus energy used to charge the battery bank.

Aurelia says the second stage of investment, required by 2025, includes the installation of six rigid, 30-meter-high sails to provide supporting wind propulsion, along with switching from fossil to biofuels.

The partnership also crafted a plan to retrofit existing Newcastle-max bulk carriers in order to meet the CO2 emissions reduction standards laid out in the Energy Efficiency eXisting ship Index (EEXI) and the CII index.

The work on the 209,000 dwt, 980-foot bulkers – operated by Oldendorff Carriers – included the installation of a Becker Mewis Duct, which enhances the flow of water to the propeller to increase thrust; a rudder bulb which changes the hub vortex to streamline the water flow behind the propeller; and a spoon bow designed to optimize the flow of water around the bow and provide optimal cargo on draft characteristics.

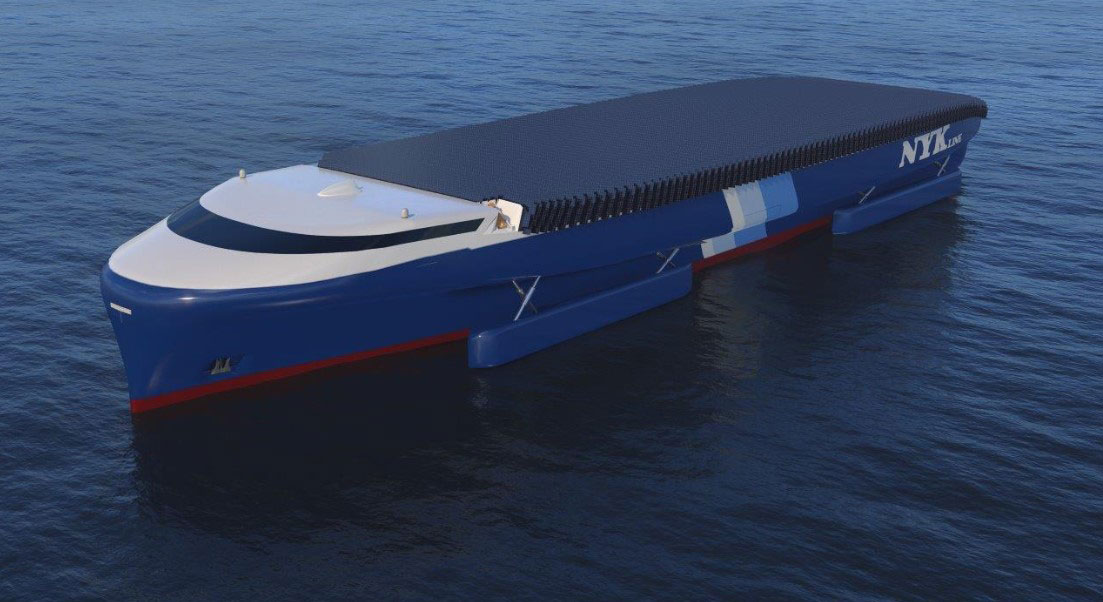

NYK’s Super Eco Ship 2050, together with MTI, the Japanese ocean carrier’s maritime R&D arm, and Finland-based engineering consultancy Elomatic, has “incorporated advantage of advancements in hull remodeling, hull weight reduction, energy conservation, and digitalization into newly design an emission-free future concept ship.”

That “advantage of advancements” features a 67 percent reduction in energy derived from fossil fuels by improving propulsion efficiency and electrical power distribution; the use of fuel cells; and a lightweight hull, as well as the use of hydrogen fuel batteries, waste heat recovery, an automated hull-cleaning robot, and solar power.

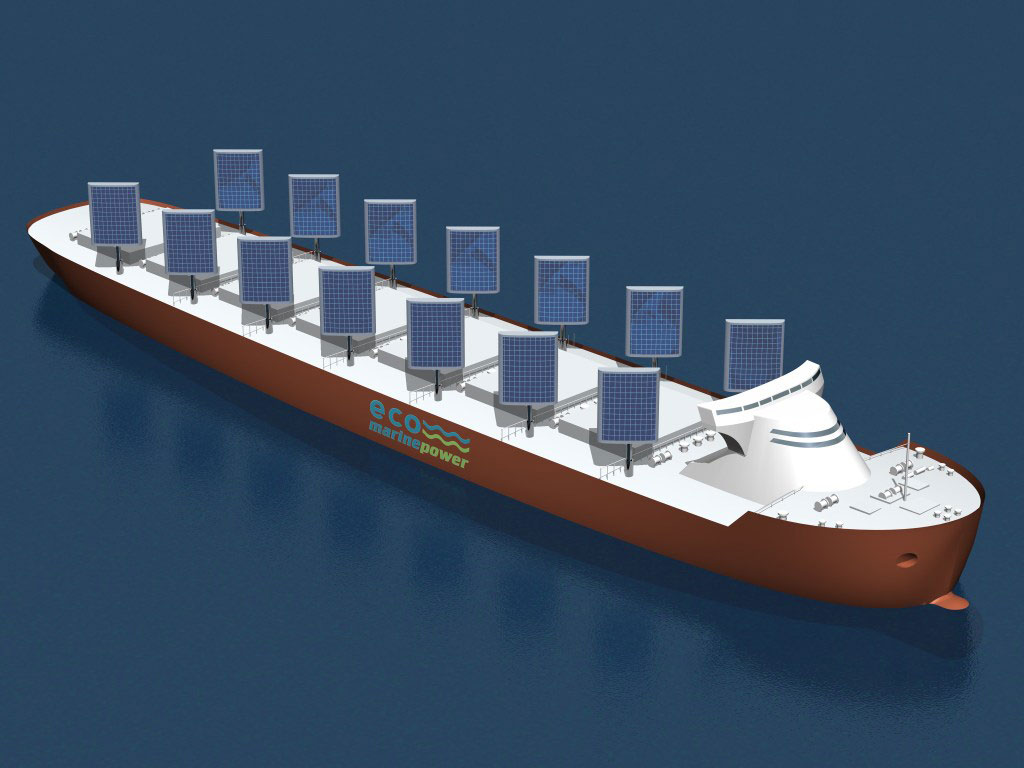

In a similar vein, Japan-headquartered Eco Marine has a similar development project underway.

Dubbed the Aquarius Eco Ship, the vessel design is “a green shipping concept design and ongoing comprehensive study project focused on optimizing the design of ocean-going ships…to harness the power of the wind and sun plus incorporate other emissions reduction and energy efficient technologies.”

Featuring rigid sails and solar power, the Aquarius Eco Ship study project was launched by Eco Marine Power Co. Ltd. in May 2011 and has attracted world-wide interest that has led to the development of several patented design concepts including the trial and commercialization of the Aquarius Marine Solar Power propulsion system.

The center piece of the Aquarius Eco Ship is its Aquarius Marine Renewable Energy (MRE) propulsion system, an innovative and patented fuel saving and emission reduction array that incorporates a variety of elements including marine-grade solar panels, energy storage modules, computer control systems and an advanced rigid sail design.

The unique bulk carrier version’s propulsion system calls for 14 rigid solar sails collecting 5,000 kw of energy that would be transferred to hybrid VRLA battery modules that power a hybrid electric engine with hydrogen fuel cells moving the 790-foot ship through the water at a maximum 16 knots.

Copenhagen-headquartered Green Ship of the Future (GSF) is a partnership and a joint initiative in which companies across the Danish Maritime Cluster joined forces “to develop and evaluate environmentally and climate friendly technologies that increase energy efficiency and reduce operational costs.”

The overall target of GSF is to reduce total CO2 emissions by 30 percent, total SOx emissions by 90 percent and total NOx emissions by 90 percent. Individual GSF projects “have come close or even surpassed these targets by achieving individual reductions of up to 25 percent for CO2, up to 98 percent for SOx and up to 80 percent NOx.

Products developed within GSF projects have been introduced on 40 Danish-owned ships. In some cases, these green ship technologies have already become standard.

The common design goals for green ship projects, as identified by GSF, include the optimization of engine efficiency to achieve significant energy savings; retro-fitting turbochargers to develop cost-saving ways to reduce emissions and improve fuel economy; the use of biocide-free paint with hydrogel coating both keeps pollutants out of the sea and reduces CO2 emissions; and reducing fuel costs by up to 8 percent by crafting new hull designs.

“Smart ship design is about building future-proof ships,” said Tuomas Timgren, CEO, Scandinavian & Baltic Evergreen Agencies at Greencarrier AB.

By using new innovative technologies to improve energy efficiency and operations to protect the environment and contribute to reducing carbon emissions, he concluded, “Ships can then operate in a smarter, safer, and more sustainable way.” •