Vane Brothers completes historic Maryland tugboat project

Vane Brothers completes historic Maryland tugboat project

Vane Brothers and Chesapeake Shipbuilding first partnered on a series of Maryland-built tugboats more than 15 years ago. With the delivery of Charles Hughes in January, that historic 20-vessel order has come to a close.

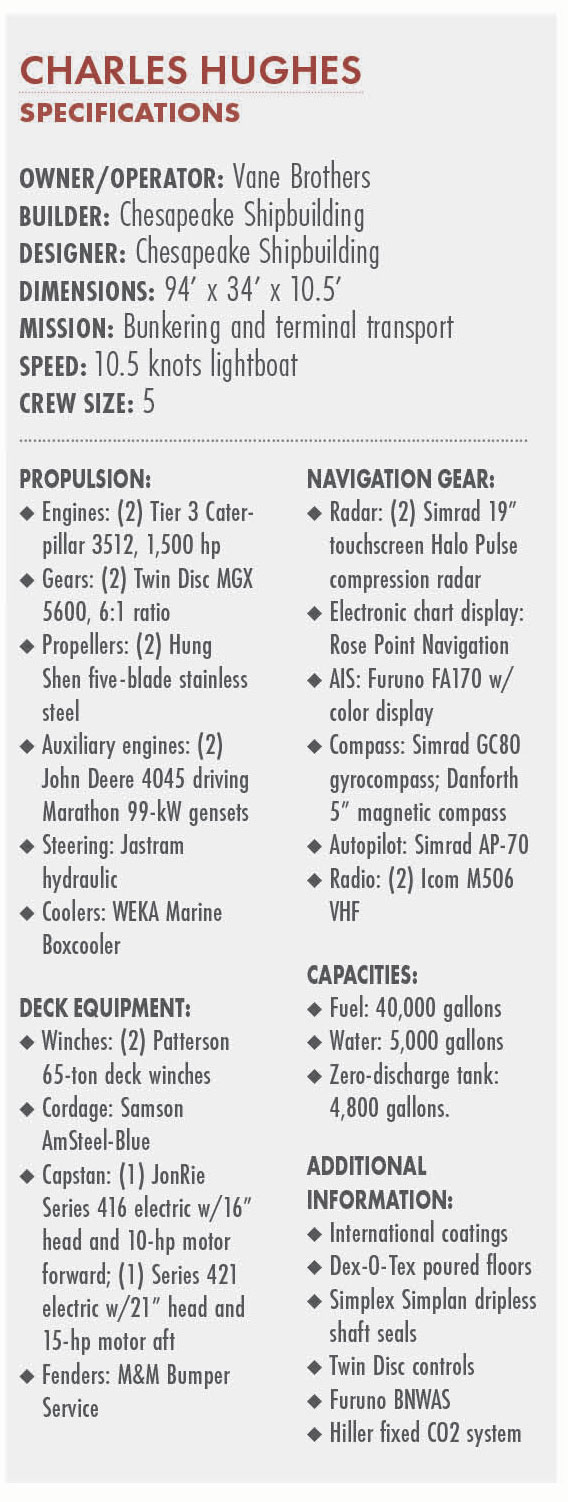

The 3,000-hp Charles Hughes is the fourth of four 94-foot pushboats designed and built at Chesapeake’s shipyard in Salisbury, Md. It joins sister tugs Salisbury, Annapolis and Rock Hall moving petroleum products around the greater Chesapeake Bay region.

“The Salisbury-class tugs were more purpose-built than the prior Chesapeake tugs,” Capt. Jim Demske, Vane’s longtime port captain who oversaw construction, recalled recently during an interview at the company’s Baltimore headquarters. “They were built especially for the shallow tributaries they were designed to be working in.”

Charles Hughes is powered by two 3,000-hp Caterpillar 3512 engines driving five-bladed steel propellers through Twin Disc gears. The design for the class came from a collaboration between Demske and John Womack, a naval architect at Chesapeake Shipbuilding.

The vessel is named for the late Charles F. Hughes Jr., the father of current Vane Brothers President C. Duff Hughes and a former chairman of the board. Hughes was a Navy veteran and graduate of Johns Hopkins University. He worked as an executive at Vane Brothers for more than 50 years.

“Vane Brothers takes pride in providing our customers and crews with vessels constructed to the highest standards,” C. Duff Hughes said in a statement. “Charles Hughes is another powerful, peak-performing tug that maximizes maneuverability where it is needed most.”

The Salisbury class, in a roundabout way, was born from the Sassafras-class tugboats that preceded them at Chesapeake Shipbuilding. In 2007, Vane Brothers ordered 20 of the 94-foot model bow tugboats designed by the noted naval architect Frank Basile.

Sassafras was delivered a year later, becoming the first Maryland-built tugboat in a generation. Fifteen sister tugs followed over the next decade that have proven their worth time and again.

The four Salisbury-class tugboats ultimately replaced what would have been the final four tugs in the Sassafras class. As the contract matured, Vane Brothers decided to replace some of its older shallow-draft pushboats working in the shallow rivers and inlets along the Chesapeake Bay, according to Demske.

One was the original Charles Hughes, a 75-foot pushboat built in the mid-1970s that Vane acquired in the early 1990s. Another was the former Roanoke, a 1960s-era towboat built by Main Iron Works in Louisiana that the new Charles Hughes replaced.

Vane Brothers’ primary businesses include bunkering ships and transporting oil and delivering oil and refined products to fuel terminals. The company’s model bow tugboats are a common presence in New York, Baltimore, Philadelphia and other large East Coast ports. Vane also operates on the West Coast, in the Gulf and Great Lakes, and into the Caribbean.

The Salisbury class fills a different niche. According to Demske, the company needed shallower-draft vessels to call on terminals throughout the Chesapeake Bay, including Salisbury, Md., which is accessible through the narrow and winding Wicomico River.

The four tugs in the class push existing 30,000-bbl double-hulled barges in the Vane Brothers fleet. They pair up through Patterson 65-ton deck winches installed on the foredeck spooled with Samson AmSteel-Blue synthetic line. When necessary, the tugs will make up to the barges on the hip using JonRie capstans forward and aft.

The winding Wicomico River is one place where that versatility pays off, particularly when they are leaving with an empty barge. “There are several turns that are more than 90 degrees, and it is tight with the piers extending out into the river,” Demske said. “So it is nice to just hip it out of there and to have that weight.”

The Salisbury class can handle its own weight in the Chesapeake, too. It can plow through 3-foot swells and has successfully navigated through seas as tall as 5 feet, according to Capt. Dustin Dise, who leads the five-person crew aboard Charles Hughes.

“The boat really does well for up here. And fast,” said Dise, who previously worked aboard the former Charles Hughes before Vane Brothers sold it to Crofton Industries. “It has great speed for low rpm. The boat does not have to be run very hard to achieve some good speeds.”

Towboats sometimes get a bad reputation for being simple box-like vessels, but the Salisbury class has some unique attributes. For one, each vessel has eight HVAC units that provide heating and cooling to different parts of the vessel. The combined system lets crewmembers customize the temperature in their cabins.

It reduced the amount of ductwork on board, which helped shave time during construction. It also will prevent fire from spreading between compartments through the ductwork. All eight units are located on the 02 deck, aft of the house.

“If one goes down, we still have enough air conditioning,” Demske said, adding that there are multiple units dedicated to the wheelhouse. “That was challenging figuring out where we were going to put all these air handlers, but I think it came out really nice.”

Keeping noise and vibration down was another priority for Demske, who has overseen construction of 48 Vane Brothers tugs and towboats over the last 20 years. That figure includes the Salisbury class, Sassafras class, Elizabeth Anne class built at St. Johns Ship Building in Florida and a smattering of ATBs built at Gulf and Great Lakes shipyards.

With the Salisbury class, Demske chose soft-core paneling to absorb unwanted sound within the crew spaces. He also selected Rock Wool insulation and Mascoat thermal acoustic paint to further deaden engine noise.

“You start building these and you are figuring out ways to make it better every time,” said Demske, who has worked for Vane Brothers for more than 32 years. “By the time you’ve done 40 or 50 of these tugs, you’ve pretty much figured out what makes a great tug, but we always find ways to improve them.”

Other crew-friendly touches include a dedicated electronics space on the 02 deck that provides much more space to troubleshoot key components. Additionally, when operating with a standard five-person crew, each person gets their own cabin.

The engine space is similar to inland towboats with an upper engine space accessible from the 01 deck that leads down to a traditional engine room. The upper space is home to steering, power panels, compressors and other critical systems. In the lower space, the twin Cat mains are located forward of the two John Deere/Marathon generators that provide electrical power. Hiller supplied the fixed CO2 fire suppression system.

Moving up from the engine room is a comfortable galley and mess on the main level outfitted with stainless steel appliances. Dex-O-Tex poured floors further help absorb noise and vibration. There are two cabins on the main deck, with the captain’s and engineer’s room on the 01 deck.

The wheelhouse layout, which has become standard across Vane Brothers’ newbuild fleet, includes helm stations in the center and on the port and starboard sides. The vessel is equipped with Simrad and Furuno navigation electronics along with a Danforth magnetic compass.

Demske fitted the base of the control panel with a folding bar that, when opened, gives the operator a better vantage point over the bow. The tug’s height of eye is 38 feet.

Primary communications happen through Icom VHF radios, and an Intellian satellite system keeps the vessel in touch during voyages further from shore. Vane installed a digital antenna and a local TV antenna that brings sports and other entertainment to the tug’s big-screen TVs.

Dise, who has captained Charles Hughes since it entered service, said the vessel is incredibly quiet and capable. It has performed well in and around Baltimore Harbor as well as longer runs as far north as Philadelphia and as far south as Norfolk, Va. “It has 3,000 hp with flanking rudders, and that is a huge benefit for getting into tight areas and turning around when we are doing bunkering operations,” Dise said. “It handles great, even in inclement weather. The winches pull tight and she handles great and can handle the chop the Bay throws at us from time to time.”

The delivery of Salisbury put Vane Brothers in a unique position of having no active newbuild program for the first time in almost 20 years. Demske characterized the break from building as a “pause” that recognizes the company’s tremendous recent construction activity. He expressed great pride in Vane’s 20 Maryland-built tugs, and what the project has meant for the region.

“The shipbuilders down (at Chesapeake) are so talented and such a good group of people,” he said. “They like building tugboats … and it’s nice to be able to draw from all of this local talent and resources for these exceptional tugs.”