(SEATTLE) — Elliott Bay Design Group (EBDG) is supporting O’Hara Corp. as it modernizes a 204-foot factory trawler, Alaska Spirit. The vessel has been successfully fishing Alaska’s Bering Sea since 1989 when it was converted from an offshore supply vessel to a head and gut factory trawler. O’Hara has committed to a complete vessel overhaul to improve habitability, efficiency and optimize vessel performance.

The multi-year project kicked off in 2017, shortly after O’Hara acquired the vessel and selected EBDG as its designated engineering partner. Project planning has been very intentional to ensure vessel operations were not negatively impacted. The modernization work completed thus far has occurred during normal down time, meaning no seasons have been missed during the process.

Upgrades have included new generator and hydraulic engines, a new factory, conversion of underutilized aft tanks to stores, replacement of pilothouse port lights with windows, habitability upgrades, and a complete rethinking of the trawl deck. EBDG has provided engineering support for much of this work while the U.S. Coast Guard has provided oversight in accordance with the Alternate Compliance and Safety Agreement (ACSA).

For habitability, O’Hara has refurbished the crew quarters including upgrades to staterooms, laundry, showering and toilet spaces. The company is currently in the planning phase for galley and mess area upgrades, expected in 2021, which will complete its accommodation improvements.

O’Hara has also added silencers to the exhaust lines of all diesel engines, substantially reducing onboard noise pollution for the crew. Prior to installation, noise on the trawl deck measured approximately 130 decibels while the main, generator and hydraulic engines were operating. Following installation of silencers, the sound level dropped to 85 dB. For the silencers, EBDG engineered two new stacks and a rebuild of one. The starboard stack aft of the amidships gantry houses the main engine silencer, and the port stack outboard of the gantry houses two silencers for the new C18 generators installed. The port stack forward of the gantry was modified to allow installation of a silencer on the new C32 hydraulics engine.

When the vessel was converted for fishing in 1989, the crew relied solely upon burtoning gear. There were no net reels installed and spare nets were carried outboard of the trawl fence. O’Hara has since removed the forward burtoning gear and installed a knuckle-boom crane. New trawl winches are being installed this year, and an equipment room is being constructed around the crane pedestal.

Next year, the existing trawl machine located at the forward end of the trawl deck will be removed. In its place will be a pair of net reels and a new Gilson gantry. The base of the gantry and reel foundations are being incorporated into an enlarged changing room for the deck crew. All these modifications have been lofted by EBDG and analyzed using finite element analysis (FEA) software.

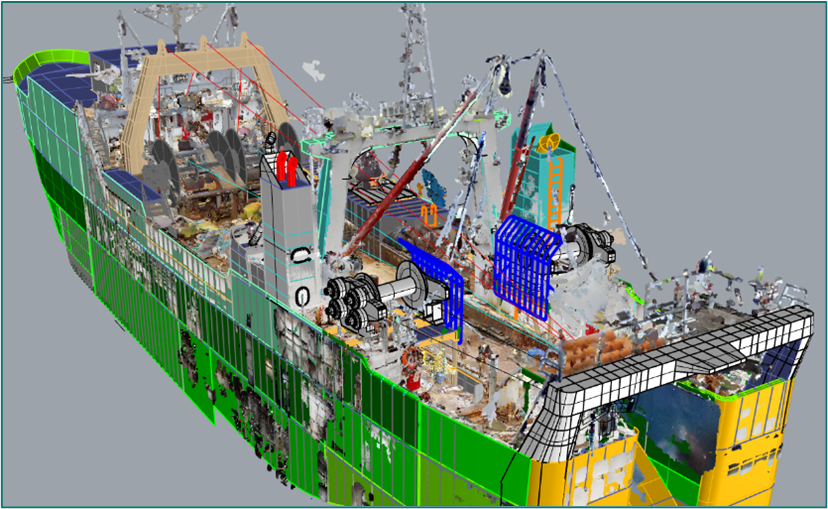

EBDG has scanned nearly the entire vessel, offering effective visual aids for O’Hara’s planning and extensive modeling.

Throughout the modification process, O’Hara has considered several different vessel options, one being the addition of a bulbous bow. EBDG investigated the addition by utilizing computational fluid dynamics (CFD) analysis.

Four different bulb geometries were considered in three conditions of vessel loading. The conclusion of the analysis was that dramatic changes in vessel trim meant a bulb could significantly improve vessel efficiency for a particular loading, but would have comparable penalties to efficiency in other conditions of loading. As a side benefit of the analysis, it was determined that modifications to the bow thruster grating, a relatively inexpensive change, could realize an efficiency gain of over 1 percent. Ultimately, O’Hara decided not to install a bulbous bow.

– Elliott Bay Design Group